Radiographic Film Processing Long Essays

Question 1. Write about the composition of X-ray film. Describe the mechanism of image formation. Write a note on the composition of developing and fixing solution and their functions.

Answer.

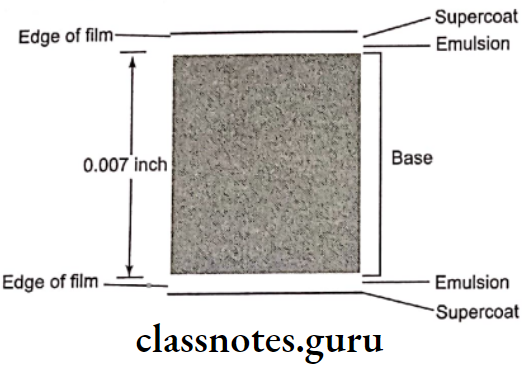

Composition Of Film:

Emulsion:

- It is sensitive to X-rays and visible light

- It records the image

- It consists of:

- Silver halide crystals

- They are composed of mainly silver bromide and lesser content of silver iodide which are photosensitive

- Each silver grain diameter is 1.8μm

- Gold may be added to improve its sensitivity

- Gelatin matrix

- It suspends silver halide crystals evenly in the gel made from cattle bone

- It absorbs the processing solution

- This allows the chemicals to react with silver halide crystals

Base:

- It is made up of Polyethylene terephthalate (polyester)

- Its diameter is 0.18mm

- The function of the base is to support the light-sensitive silver halide crystals

- The base is a slightly blue-tinted to enhance the image quality

- Its translucency cast no patterns on the resultant radiograph

- It withstands exposure during processing without distortion

- It is flexible for proper handling

- Adhesive layer

- It is applied to the base before the emulsion is applied for proper adaptation

Radiographic film processing long essay

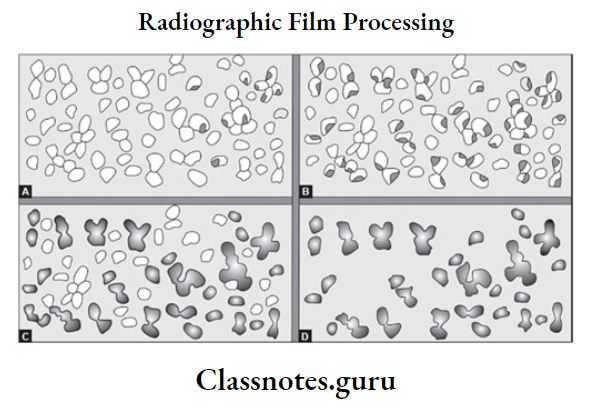

Formation Of Image:

- The film emulsion is made up of silver bromide crystals and silver iodide crystals that are precipitated in gelatin

- When the silver halide crystals are irradiated by X-ray photons it will result in the release of electrons usually by the bromide ions

- This leads to the conversion of bromide ions to bromine atoms by removing electrons

- This recoil electron thus produced has sufficient kinetic energy with which it moves in the crystal and strikes the image site

- This imparts a negative charge to that region

- The free positively charged interstitial silver ions are attracted to the negative latent image site

- This neutralizes the image site with the result that an atom of metallic silver is deposited at the site

- After exposure of a film to radiation, the aggregate of silver atoms at the latent image sites comprises the latent image

Read And Learn More: Oral Radiology Question and Answers

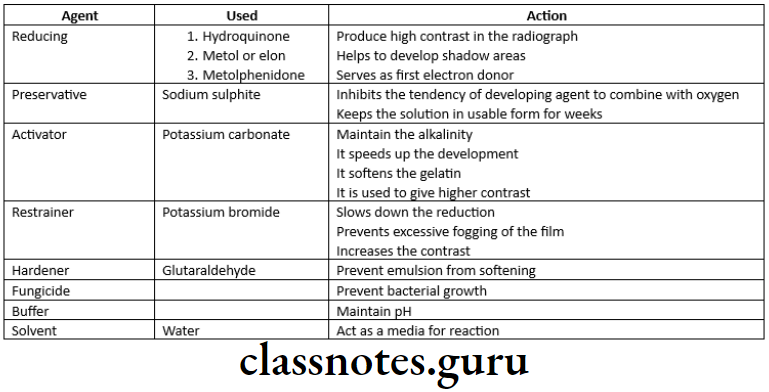

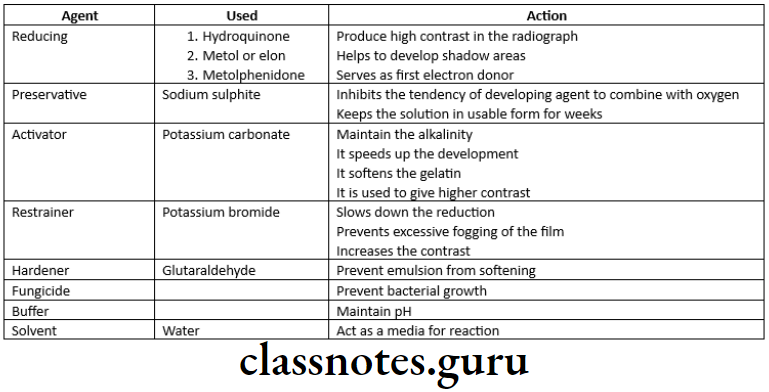

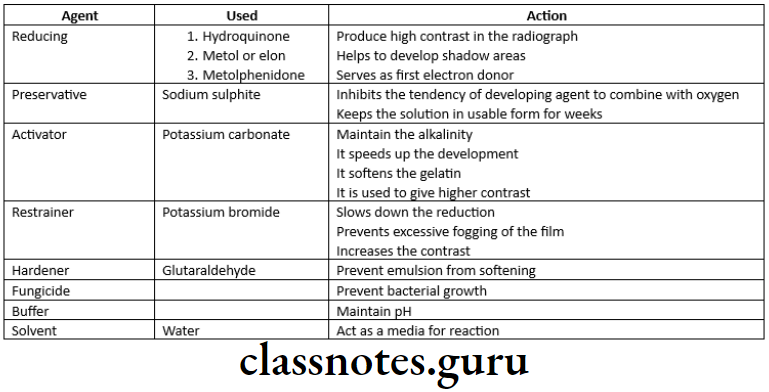

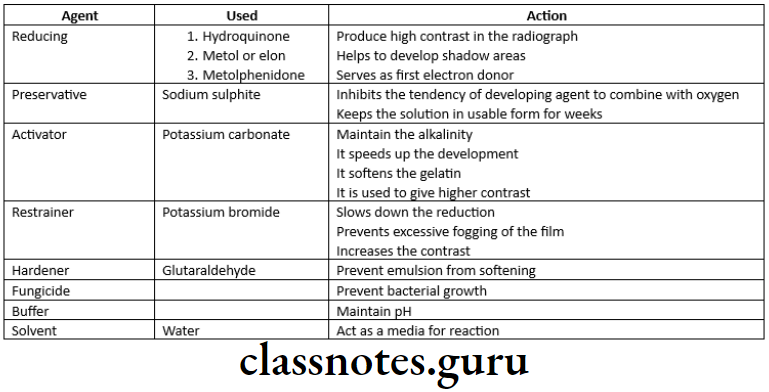

Composition Of Developer:

Film processing in radiology essay

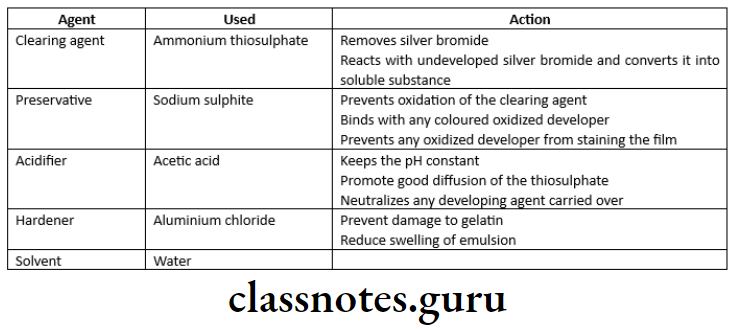

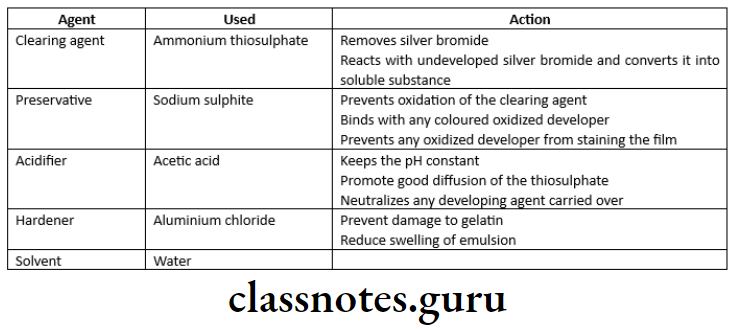

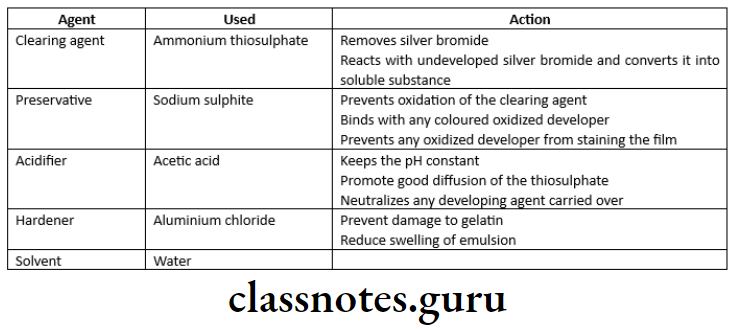

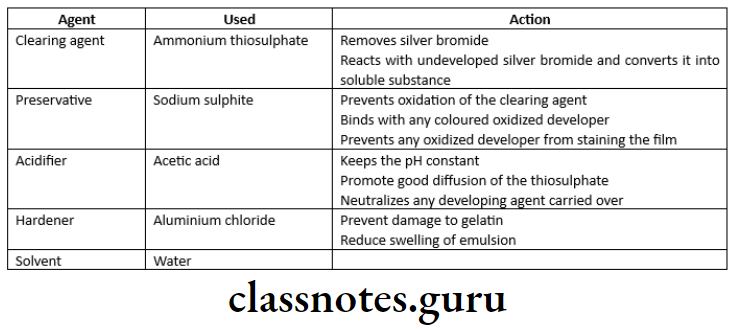

Fixing Solution

Question 2. Write in detail about the processing of X-ray film.

Or

Enumerate various film processing techniques. Describe in detail the manual procession.

Answer.

x-ray film Types:

- Manual method:

- Time-temperature

- Visual method

- Rapid processing method

- Automatic method:

- Monobath method

- Daylight method

- Digitalized processing method

- Self-developing films

Time Temperature Method:

- Initially replenish the developer & fixer solutions

- Set the temperature of the developer

- Unwrap the film

- Hold the film along the sides, & clip it to the hanger

- Agitate the film

- Keep it for the predetermined time

- After that place it in the circulating water

- Agitate for 20 – 30 seconds to remove excess solution

- According to the time & temperature of the developer, set that of the fixer

- Immerse the film in The Fixer

- Agitate for 5 of every 30 seconds

- After it, allow to drain the excess fixer solution

- Place it in circulating water for at least 20 minutes

- Dry the film

Visual Method:

- Place the film in the developer

- View them from time to time

- Look for the degree of darkness in the safelight

x-ray film Advantages:

- Developing to desired darkness is possible

- Fewer chances of errors

x-ray film Disadvantages:

- Individually processing required

- Thus, time-consuming

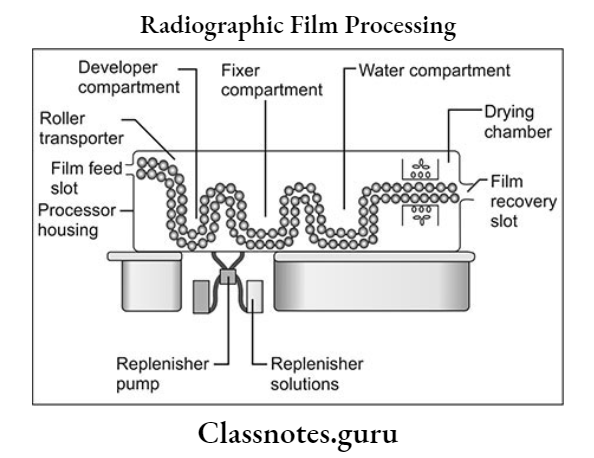

Automatic Film Processing

- This method uses equipment that automates all the processing steps

Automatic Film Processing Advantages:

- Rapid process

- Uniformity of the results is obtained

- Less space required

- The density and contrast of the film are consistent

Automatic Film Processing Disadvantages:

- Low quality as compared to that processed manually

- High cost of equipment

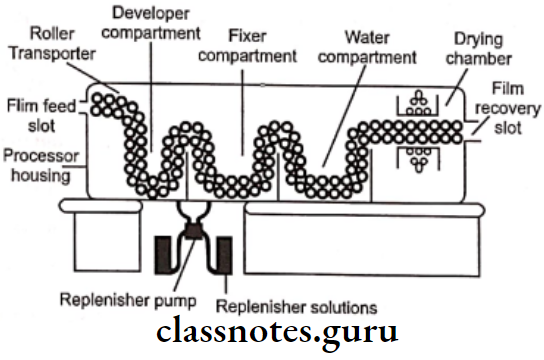

Automatic Film Processing Mechanism:

- The apparatus consists of a transport mechanism

- This picks up the unwrapped films which are passed through the developer, fixer, and drying sections

- The system uses a series of rollers driven by a constant-speed motor that operates through gears, belts, or chains

- The rollers consist of assemblies of multiple rollers

- It is so designed that the film crosses over from one roller to the next

- The operator may also be able to remove them independently for soaking, cleaning, and repairing

Radiographic film processing short essay

Question 3. Formation of latent image. Add a note about a fixer and developer solution

Answer.

Formation Of Image:

- The film emulsion is made up of silver bromide crystals and silver iodide crystals that are precipitated in gelatin

- When the silver halide crystals are irradiated by X-ray photons it will result in the release of electrons usually by the bromide ions

- This leads to the conversion of bromide ions to bromine atoms by removing an electron

- This recoil electron thus produced has sufficient kinetic energy with which it moves in the crystal and strikes the image site

- This imparts a negative charge to that region

- The free positively charged interstitial silver ions are attracted to the negative latent image site

- This neutralizes the image site with the result that an atom of metallic silver is deposited at the site

- After exposure of a film to radiation, the aggregate of silver atoms at the latent image site comprises the latent image

Fixing Solution:

Composition Of Developer

Radiographic Film Processing Short Essays

Question 1. Developer and fixing solution.

Answer.

Composition Of Developer:

Steps of radiographic film processing

Fixing Solution:

Question 2. Formation of latent image.

Answer.

Formation of the latent image

- The film emulsion is made up of silver bromide crystals and silver iodide crystals that are precipitated in gelatin

- When the silver halide crystals are irradiated by X-ray photons it will result in the release of electrons usually by the bromide ions

- This leads to the conversion of bromide ions to bromine atoms by removing an electron

- This recoil electron thus produced has sufficient kinetic energy with which it moves in the crystal and strikes the image site

- This imparts a negative charge to that region

- The free positively charged interstitial silver ions are attracted to the negative latent image site

- This neutralizes the image site with the result that an atom of metallic silver is deposited at the site

- After exposure of a film to radiation, the aggregate of silver atoms at the latent image site comprises the latent image

Question 3. Film processing.

Answer.

Film Processing Types:

- Manual method:

- Time-temperature

- Visual method

- Rapid processing method

- Automatic method:

- Monobath method

- Daylight method

- Digitalized processing method

- Self-developing films

Time Temperature Method:

- Initially replenish the developer & fixer solutions

- Set the temperature of the developer

- Unwrap the film

- Hold the film along the sides, & clip it to the hanger

- Agitate the film

- Keep it for the predetermined time

- After that place it in the circulating water

- Agitate for 20 – 30 seconds to remove excess solution

- According to the time & temperature of the developer, set that of the fixer

- Immerse the film in The Fixer

- Agitate for 5 of every 30 seconds

- After it, allow to drain the excess fixer solution

- Place it in circulating water for at least 20 minutes

- Dry the film

Manual film processing in radiography

Film Processing Visual Method:

- Place the film in the developer

- View them from time to time

- Look for the degree of darkness in the safelight

Film processing Advantages:

- Developing to desired darkness is possible

- Fewer chances of errors

Film processing Disadvantages:

- Individually processing required

- Thus, time-consuming

Question 4. Manual film processing.

Answer.

Time Temperature Method:

- Initially replenish the developer & fixer solutions

- Set the temperature of the developer

- Unwrap the film

- Hold the film along the sides, & clip it to the hanger

- Agitate the film

- Keep it for the predetermined time

- After that place it in the circulating water

- Agitate for 20 – 30 seconds to remove excess solution

- According to the time & temperature of the developer, set that of the fixer

- Immerse the film in The Fixer

- Agitate for 5 of every 30 seconds

- After it, allow to drain the excess fixer solution

- Place it in circulating water for at least 20 minutes

- Dry the film

Manual Film Processing Visual Method:

- Place the film in a developer

- View them from time to time

- Look for the degree of darkness in the safelight

Manual Film Processing Advantages:

- Developing to desired darkness is possible

- Fewer chances of errors

Manual Film Processing Disadvantages:

- Individually processing required

- Thus, time-consuming

Question 5. Automatic Film Processing.

Answer.

Automatic Film Processing

- This method uses equipment that automates all the processing steps

Automatic Film Processing Advantages:

- Rapid process

- Uniformity of the results is obtained

- Less space required

- The density and contrast of the film are consistent

Automatic Film Processing Disadvantages:

- Low quality as compared to that processed manually

- High cost of equipment

Automatic Film Processing Mechanism:

- The apparatus consists of a transport mechanism

- This picks up the unwrapped films which are passed through the developer, fixer, and drying sections

- The system uses a series of rollers driven by a constant-speed motor that operates through gears, belts, or chains

- The rollers consist of assemblies of multiple rollers

- It is so designed that the film crosses over from one roller to the next

- The operator may also be able to remove them independently for soaking, cleaning, and repairing

Automatic film processing radiology essay

Question 6. Coin test.

Answer.

Coin test AIM:

- To evaluate safelight requirements

Coin test Method:

- Shut all the lights

- Put on the safe light

- Open the film packet

- Place the film over the unwrapped surface

- Place a coin over it

- Leave it for approximately the time required for unwrapping the full-mouth radiograph which is about 5 minutes

- Develop the film

Coin test Result:

- If the image of the coin can be seen on the resultant film, the room is not light-safe

Radiographic Film Processing Short Answers

Question 1. Latent image.

Answer.

Latent image

- When the radiographic film is exposed to the information-carrying beam of photons exiting an object, the photosensitive silver halide crystals in the film emulsion interact with these photons and are chemically changed

- These chemically altered crystals constitute the latent image of the film

- This increases the liability of crystals to the chemical action of the developing process that converts the latent image into a visible image

Question 2. Composition of developer

Answer.

Composition Of Developer:

Essay on X-ray film processing

Question 3. Fixing solution

Answer.

Fixing Solution:

Radiographic darkroom procedure essay

Question 4. Darkroom requirements.

Answer.

Size:

- 3 feet x 3 feet for an individual dentist

- 16 – 20 square feet for group practice

- Should have sufficient space to accommodate the processing tanks

- It must include an adequate working area where the films are unwrapped

- It must contain a storage space

- It should be well-ventilated

- Room temperature must be 70 degrees

- Humidity levels must be between 50-70%

- The room must include both hot & cold running water

- Wastebasket for disposal of all film wrappings

- Safe light mounted on the wall or ceiling

- It should be at least 4 feet from the work surface

Film development and fixing short notes

Radiographic Film Processing Viva Voce

- The height of safe light from the working area should be 1.22m [4 feet]

- The temperature of X-ray processing tanks should be between 60-75°F

- In developer, sodium sulfite acts as a preservative

- Hydroquinone in developer is added to increase the contrast of the image