Impression Materials Important Notes

1. Classification Of Impression Materials

- Based On Setting Mechanisms

- Chemical reaction

- Plaster of Paris — Zinc oxide eugenol

- Alginate

- Nonaqueous elastomers

- Thermally-induced physical reaction

- Compound wax

- Agar

- Chemical reaction

- Based On Elasticity

- Rigid materials

- Plaster of Paris

- Zinc oxide eugenol

- Compound

- Rigid materials

- Elastic Material

- Agar

- Alginate

- Non-aqueous elastomers

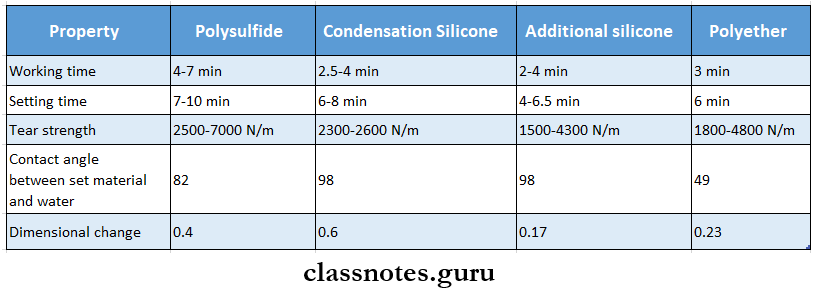

2. Types Of Elastomers

3. Addition Silicone

- Addition Silicone are type II silicone impression materials

- In addition Silicone undergoes an additional type of polymerization terminating in vinyl groups and cross-linked with hydride group

- In addition Silicone has very little residual polymerization

- Thus it is the most dimensionally stable

- Addition Silicone is highly biocompatible

- Addition Silicone Advantages:

- Dimensionally stable

- Adequate tear strength

- Pleasant odor and color

- Multiple casts can be made from one impression

- No volatile byproduct

- Addition Silicone Disadvantage

- Impurities evolve hydrogen gas

- This hydrogen gas produces pinpoint voids in the stone casts if poured immediately

- It is prevented by

- Adding platinum or palladium

- By delaying the pouring of impression

Read And Learn More: Dental Materials Question and Answers

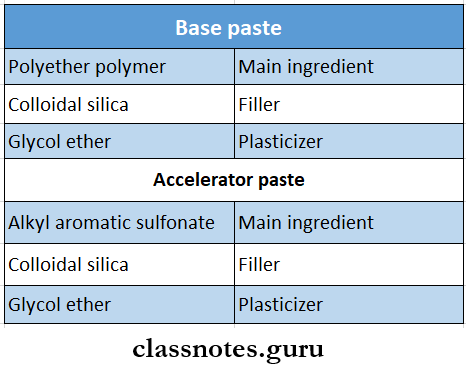

4. Composition Of polyether Impression Material

5. Impression Techniques

- Multiple Mix technique

- Two separate mixes are made

- Heavy body material is placed in the tray

- Light body is loaded in a syringe

- Impression is made

- Single Mix

- Only one mix is made

- Medium body material is used

- Part of it is loaded in a tray and part is loaded in a syringe

- Impression is made

Alginate Impression Material

6. Causes Of The Rough Surface Of Elastomers

- Incomplete polymerization caused by premature removal from the mouth

- The improper ratio of mixing components

- Too rapid polymerization caused by high humidity and high temperature

Impression Materials Long Essay

Question 1. State the properties and uses of rubber-based materials

Answer:

Rubber Based Materials:

Rubber Based Materials Synonyms:

- Rubber impression materials

- Elastomeric impression materials

Rubber Based Materials Properties:

- They are accurate impression material- they excellently reproduce the surface details

- They are dimensionally stable

- Available in various viscosity

- The low viscosity is capable of reproducing even very fine details

- They are generally hydrophobic

- Resilience

- They are flexible with near-complete elastic recovery

- Its coefficient of thermal expansion Is high

- It cannot melt, before melting they pass Into a gaseous state

- They swell In the presence of certain solvents

- They are Insoluble

- They have lower creep resistance

- Tear strength is excellent

- They can be electroplated

- As they don’t adhere well to the Impression tray, tray adhesive is used

- It has a shelf life of about two years

- It may cause dimensional changes due to

- Curing shrinkage

- Loss of byproducts

- Hydrophilic nature

- Thermal contraction

- Delayed pouring of cast

Rubber Based Materials Uses:

- In fixed partial dentures for Impressions of prepared teeth

- Impressions of dentulous mouths for removable partial dentures

- Impressions of edentulous mouths for complete dentures

- Polyether Is used for border molding

- For bite registration

- Silicon Is used for making refractory casts

Dental Impression Techniques

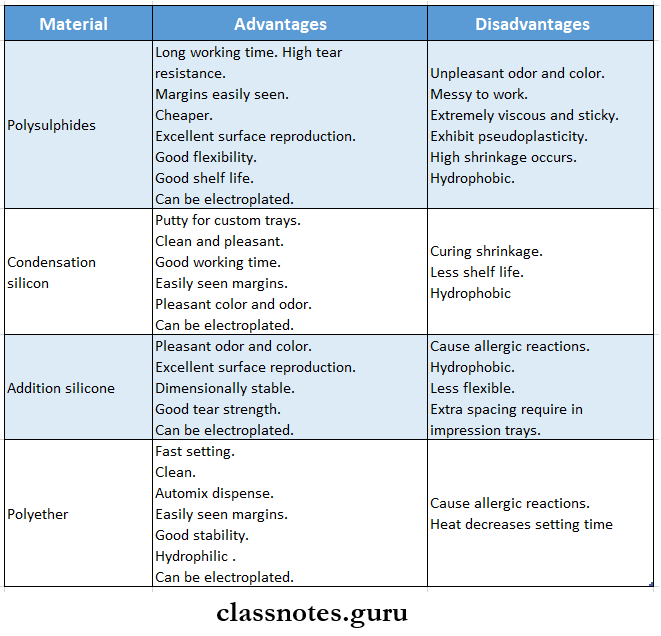

Question 2. Advantages and disadvantages of elastomeric Impression material

Answer:

Advantages And Disadvantages Of Elastomeric Impression Material

Question 3. What are elastomers? Write in detail about the types, composition, properties, and manipulation of additional silicone impression material.

Answer:

Elastomers:

- It is a lightly cross-linked impression material that exhibits elastic behavior after setting.

- It refers to a group of rubbery polymers, which are either chemically or physically cross-linked

Addition Silicones:

Addition Silicones Types:

- It is available in four viscosities

- Light bodied

- Medium bodied

- Heavy bodied

- Putty

Addition Silicones Composition:

![]()

Addition Silicones Properties:

![]()

- Setting time-5-9 minutes

- Mixing time- 45 seconds

- Shelf life 1 to 2 years

Manipulation:

1. For The Paste

- Dispense equal length of base and catalyst over a mixing pad

- Incorporate first the catalyst into the base

- Mixing is done by moving the spatula back and forth on the mixing pad

- The process is continued until the mixed paste is uniform in color with no streaks of the base or catalyst

2. For Putty

- An equal number of scoops of each putty is dispensed

- Material is then kneaded with fingers until a uniform color is obtained

Question 4. Classify impression materials and describe in detail about contents, setting, and properties of silicone rubber base impression materials

Answer:

Silicone Rubber Classification:

1. Based On Setting Mechanisms

- Chemical Reaction

- Plaster of Paris

- Zinc oxide eugenol

- Alginate

- Nonaqueous elastomers

- Thermally-Induced Physical Reaction

- Compound wax

- Agar

2. Based On Elasticity

- Rigid Materials

- Plaster of Paris

- Zinc oxide eugenol

- Compound wax

- Elastic Material

- Agar

- Alginate

- Nonaqueous elastomers

Silicon Rubber Based Materials: Silicon rubber-based materials are

- Condensation silicone

- Addition silicone

![]()

Impression Materials Short Essays

Question 1. What are nonaqueous elastomers and write any one of their compositions?

Answer:

Nonaqueous Elastomers:

Nonaqueous elastomers are

- Polysulphides

- Polyether

- Condensation silicone

- Addition Silicones

![]()

Accuracy Of Impression Materials

Question 2. Ideal requirements of Impression materials

Answer:

Ideal Requirements:

- They should be fluid enough to adapt to oral tissues

- Should be viscous enough to be contained in the tray that is seated in the mouth

- While in the mouth, they should set into a rubbery or rigid solid in a reasonable amount of time

- The set impression should not tear or distort when removed

- The impression made should be dimensionally stable

- Stability should be maintained after the removal of a cast so that a second or third cast can be made

- The material should be biocompatible

- It should be cost-effective

- Should be nontoxic

- Should be acceptable to patients with pleasant odor and color

- Should have an adequate shelf life

- Easy to use with minimum equipment

- Should have adequate strength

- Should be compatible with the die and cast materials

- Should be able to be electroplated

Question 3. Polysulphides

Answer:

Polysulphides

Polysulphides were the first elastomeric impression material to be introduced

Polysulphides Advantages:

- Long working time

- High tear resistance

- Margins easily seen

- Cheaper

- Excellent surface reproduction

- Good flexibility

- Good shelf life

- Can be electroplated

Polysulphides Disadvantages:

- Unpleasant odor and color

- Messy to work

- Extremely viscous and sticky

- Exhibit pseudo plasticity

- High shrinkage occurs

- Hydrophobic

Polysulphides Composition:

- Base

- Liquid polysulfide polymer

- Inert fillers

- Reactor

- Lead dioxide

- Dibutyl phthalate

- Sulfur

- Other substances like magnesium stearate and deodorants

Advantages And Disadvantages Of Impression Materials

Question 4. Elastomers

Answer:

Elastomers

- A lightly cross-linked impression material that exhibits elastic behavior after setting is called elastomer

- They contain large molecules with weak Interaction between them

- They are liquid polymers that can be converted to solid rubber at room temperature

Elastomers Types:

1. According to Chemistry

- Polysulphides

- Condensation silicone

- Addition silicone

- Polyether

2. According to Viscosity

- Light body

- Medium body

- Heavy body

- Very heavy body

3. According to Elasticity

- Type 1

- Type 2

- Type 3

4. According to Wettability

- Hydrophilic

- Hydrophobic

Elastomers Uses:

- In fixed partial dentures for impressions of prepared teeth

- Impressions of dentulous mouths for removable partial dentures

- Impressions of edentulous mouths for complete dentures

- Polyether is used for border molding

- For bite registration

- Silicon is used for making refractory casts

Question 5. Reline technique for elastomeric impression

Answer:

Reline Technique For Elastomeric Impression

- Reline technique is also called the two-stage putty wash technique

- It is used to minimize the effect of Polymerisation shrinkage

Elastomeric Impression Technique:

- The thick putty material is made using a stock tray

- Results in preliminary impression

- Spacing is provided by either

- Cutting away some of the tray putties or

- Using a thin polyethylene sheet between putty and prepared tooth

- The mix of thin consistency wash material is placed into putty

- Putty wash and tray are seated into the mouth

- The final impression is made

Classification Of Impression Materials

Question 6. Condensation silicon

Answer:

Condensation Silicon

Condensation silicone is one of the silicone impression material

Condensation Silicon Composition:

1. Base

- Polymethyl siloxane

- Colloidal silica

- Color pigments

2. Accelerator

- Orthoethyl silicate

- Stannous octoate

Condensation Silicon Advantages:

- Putty for custom trays

- Clean and pleasant

- Good working time

- Easily seen margins

- Pleasant color and odor

- Can be electroplated

Condensation Silicon Disadvantages:

- Curing shrinkage

- Less shelf life

- Hydrophobic

Impression Materials Short Question And Answers

Question 1. Rubber-based impression material

Answer:

Rubber-Based Impression Material

- It is a lightly cross-linked impression material that exhibits elastic behavior after setting.

- It refers to a group of rubbery polymers, which are either chemically or physically cross-linked

Rubber-Based Impression Material Uses:

- In fixed partial dentures for impressions of prepared teeth

- Impressions of dentulous mouths for removable partial dentures

- Impressions of edentulous mouths for complete dentures

- Polyether is used for border molding

- For bite registration

- Silicon is used for making refractory casts

Properties Of Dental Impression Materials

Question 2. Addition silicone

Answer:

In addition, silicone is the most widely used impression material

Addition Silicone Advantages:

- Pleasant odor and color

- Excellent surface reproduction

- Dimensionally stable

- Good tear strength

- Can be electroplated

Addition Silicone Disadvantages:

- Cause allergic reactions

- Hydrophobic

- Less flexible

- Extra spacing is required in impression trays

Question 3. Cross-linking

Answer:

Cross-linking

The joining of polymer chains to form a three-dimensional network structure is called cross-linking

Question 4. Polyether

Answer:

Polyether

- Polyether was introduced in Germany

- It has good mechanical properties and dimensional stability

Polyether Advantages:

- Fast setting

- Clean

- AutomLx dispense

- Easily seen margins

- Good stability

- Hydrophilic

- Can be electroplated

Polyether Disadvantages:

- Cause allergic reactions

- Heat decreases the setting time

Properties Of Dental Impression Materials

Question 5. Tray adhesives.

Answer:

Tray Adhesives

- Tray adhesives are tacky liquids that are applied with a brush

- They are used to obtain the most accurate impression possible by adhering impression material to the tray

- Tray Adhesives is advisable to use tray adhesive on all trays before making an impression

Each elastomer has a specific adhesive

Tray Adhesives Method Of Application:

- Apply a thin layer of tray adhesive to the tray using the applicator brush

- Allow to dry for at least 3 minutes

- Load the tray with impression material

- Make an impression

Question 6. Multiple mix impression technique of elastomers.

Answer:

Multiple Mix Impression Techniques Of Elastomers

- Two separate mixes are made

- Heavy body material is placed in the tray

- Light body is loaded in a syringe

- Impression is made