Direct Filling Gold Short Essays

Question 1. DFG (Direct Filling Gold).

Answer:

DFG (Direct Filling Gold):

Direct Filling Gold Definition:

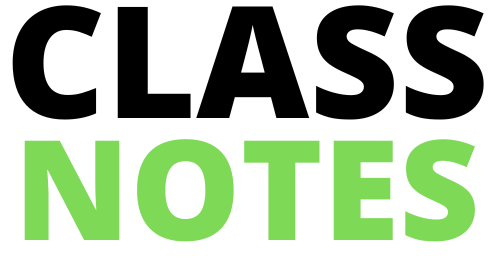

- Direct gold is a gold restorative material that is manufactured for compaction directly into prepared cavities

Direct Filling Gold Indications:

- Class 1 cavities Small carious lesions in pit and fissures of posterior teeth

- Class 5 carious lesions

- Class 3 cavities proximal surfaces of anterior teeth

- Class 2 restoration of small cavitated proximal surfaces of posterior teeth

- Class 6 Incisal edges or cusp tips

- A defective margin of cast metal restoration

Direct Filling Gold Contraindications:

- Very large pulp chambers

- Severely periodontally weakened teeth with questionable prognosis

- In handicapped patients

- Root canal-filled teeth

Direct Filling Gold Classification:

1. Foil:

- Sheet

- Cohesive

- Noncohesive

- Ropes

- Cylinders

- Laminated foil

- Platinized foil

2. Electrolytic Precipitate:

- Mat gold

- Mat foil

- Gold calcium alloy

Read And Learn More: Operative Dentistry Short And Long Essay Question And Answers

Question 2. Types Of Gold.

Answer:

Types Of Gold:

1. Gold Foil Oldest Form:

Types:

1. Sheets Size 10 x 10 cm

- Thickness 1.5 micron

- No.3 weighs 3 gm

- Too large for use in preparation

2. Gold Foil Cylinder

- Uses noncohesive gold

- Uses % and 1/8 of a sheet of gold

3. Gold Pellets

- Are annealed before the formation

- Stored in a gold foil box along with a cotton dipped in 18% ammonia

4. Platinized Gold Foil

- Platinum content in foil is 15%

- Increased hardness

- Used for restoration of cusp tips and incisal edges

5. Corrugated Gold Foil.

- Paper placed between foil gets burnt and charred

4. Laminated Gold Foil:

- More resistant to applied forces

2. Crystalline Gold

1. Mat Gold

- Electrolytically precipitated type

- Used for building up of internal restoration

2. Mat Foil

- No need to veneer the restoration

3. Electralloy

Increased hardness and strength of gold by adding minute quantities as Calcium

Improved handling properties

4. Powdered Gold

- Size 15 microns

- Difficult to handle

- Does not require very sharp line angles and point angles.

Question 3. Mat Gold.

Answer:

- Electrolytically precipitated

Mat Gold Preparation:

- Sinter pure gold in the oven

- Heat slightly below its melting point

Mat Gold Result:

- Spongy, loosely arranged crystalline structure

- Available in form of strips

- Can be used plain/sandwiched in gold foil

- Mat Gold Use: Building up of internal restoration

- Mat Gold Advantage: Easily compacted

- Adapted well

Question 4. Condensation of DFG.

Answer:

Condensation Of DFG:

Condensation Of DFG Aims:

- Formation of cohesive mass

- Adaptation to the preparation margins

- Prevent voids formation

- Increases strength and hardness of restoration

Condensation Of DFG Technique:

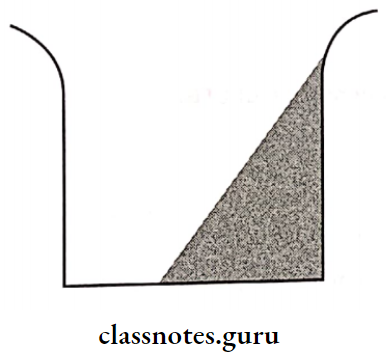

- Place the gold piece in the corner of the preparation

- Start malleting in the center of the mass

- Condense at 45o to walls and floor for maximum adaptation

- Next condense at 90° to the previous layer to prevent displacement of already condensed pieces

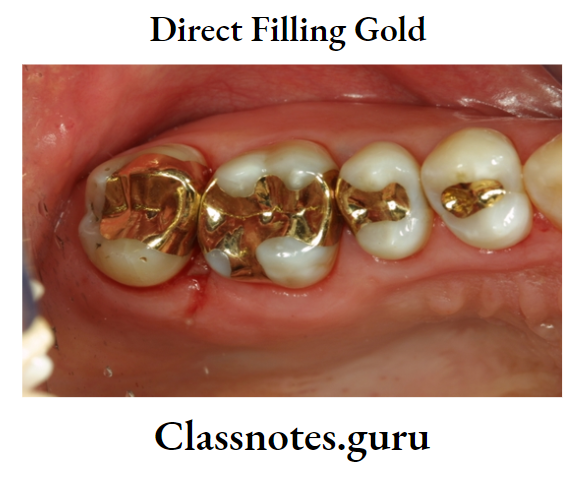

- Each time the condenser should overlap the half of previous step for reducing voids formation

- This is called stepping

Question 5. Annealing/Degassing.

Answer:

Annealing:

- Annealing involves the removal of the volatile protective coating present on a pure gold surface

- Used for noncohesive gold, as a layer of ammonia is present over it to prevent the formation of the oxide layer and contaminate gold

Annealing Methods:

1. Using Alcohol Flame:

- Bulk Method:

- Place mass of gold in mica tray and heat over flame up to 650700°C

- Less time required

- Risk of overheating

- In The Piece Method;

- Hold small pieces over a blue flame of alcohol and heat until the gold becomes dull red

- Less wastage

- Time consuming

2. Electric Annealer:

- Gold is heated for 10 minutes at 850°F

- Then cooled for placing in the prepared tooth

Direct Filling Gold Short Answers

Question 1. Preparation of Pure gold foil.

Answer:

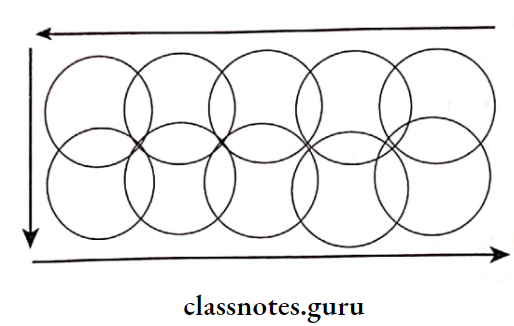

Preparation Of Pure Gold Foil:

- Gold foil are cut into sheets

- These sheets are separated by papers

- These are heated together

- 20 such papers are consist in the book

- These sheets are cut into different sizes and are available in different weight

Question 2. Properties of DFG (Direct Filling Gold)

Answer:

Properties Of DFG (Direct Filling Gold):

- Direct Filling Gold soft, malleable, and ductile

- Direct Filling Gold does not get oxidized

- Direct Filling Gold is yellowish, metallic in color

- Direct Filling Gold get fuses at 1063oC and boils at 2200oC

- The density of gold is 1919.3 g/cm2

- Direct Filling Gold hardness is 25 BHN

- Direct Filling Gold coefficient of thermal expansion is 14.4 x 106/oC which is more than that of a tooth

- Direct Filling Gold is the noblest of all metals

- Direct Filling Gold has high thermal conductivity

- Direct Filling Gold can be cold welded

- Direct Filling Gold results in good marginal integrity

Question 3. Electrically.

Answer:

Electrically:

- The newest form of DFG

DFG Preparation:

- Electrolyte it along with the addition of minute quantities of calcium

- The resultant crystalline structure is sandwiched between two gold foils

DFG Advantages:

- Improved handling properties

- Produces the hardest surface

- Increased strength and hardness

Question 4. Gold Foil.

Answer:

Gold Foil:

Gold Foil Types:

1. Sheets Size 10 x 10 cm

- Thickness 1.5 micron

- No.3 weighs 3 gm

- Too large for use in preparation

2. Gold Foil cylinder

- Uses noncohesive gold

- Uses % and 1/8 of a sheet of gold

3. Gold Pellets

- Are annealed before the formation

- Stored in a gold foil box along with a cotton dipped in 18% ammonia

4. Platinized Gold Foil

- Platinum content in foil is 15%

- Increased hardness

- Used for restoration of cusp tips and incisal edges

5. Corrugated Gold Foil

- Paper placed between foil gets burnt and charred

6. Laminated Gold Foil

- More resistant to applied forces

Direct Filling Gold Viva Voce

- All types of DFG except non corrosive gold require degassing before use

- Underheating fails to render the gold surface pure

- Overheating makes the gold more brittle

- Poor resistance form can result in tooth fracture

- Improper retention form results in loose restoration

- Forces of condensation should be at 45° to the cavity walls and floors

- Forces of condensation must be at 90° to previously condensed gold