Dental Waxes Important Notes

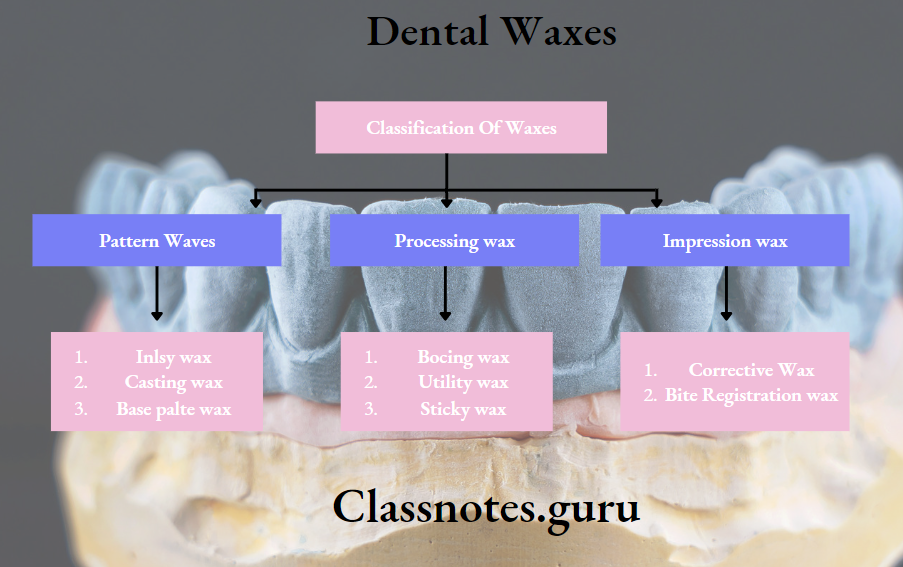

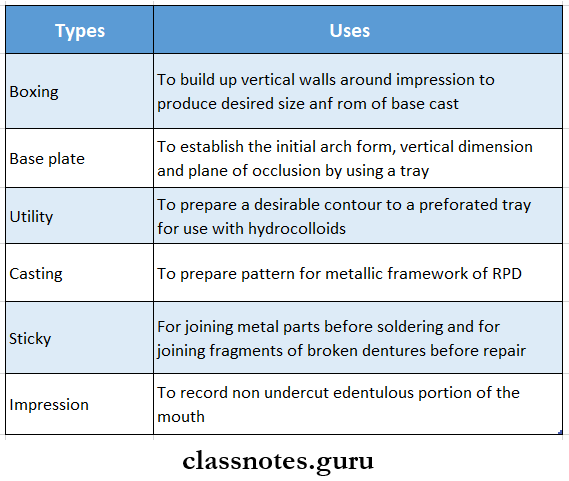

1. Classification of Waxes

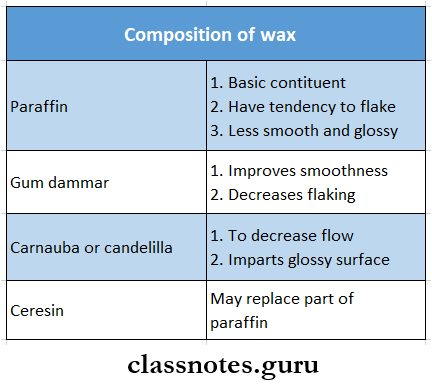

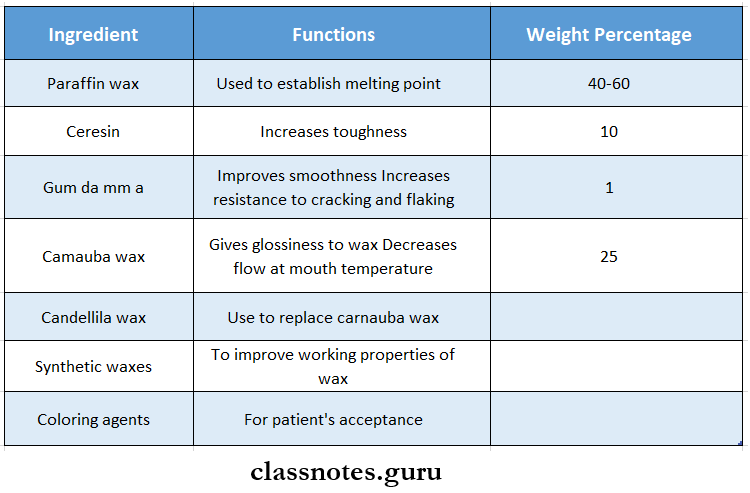

2. Composition of Wax Paraffin

3. Technique

Dental Wax Materials

4. Types Of Waxes And Their Uses

5. Components of Base Plate Wax

- Paraffin – 75%

- Bee’s wax-12%

- Added colors

Read And Learn More: Dental Materials Question and Answers

Dental Waxes Long Essays

Question 1. Describe the composition, properties, and manipulation of inlay wax.

Answer:

Inlay Wax:

Inlay Wax Composition:

Inlay Wax Properties:

1. Inlay Wax Flow

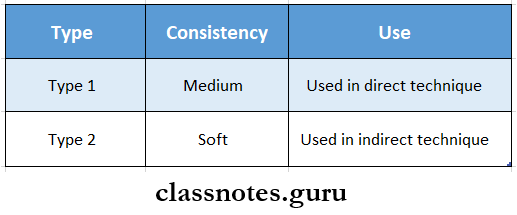

- Ideally, type I inlay wax should exhibit marked plasticity or flow at a temperature slightly above the mouth temperature

- At 45 degrees C- both types should have a flow between 70-90%

- At 37 degrees C- the type should not flow more than 1%

- At 30 degrees C- type 2 should not flow more than 1%

2. Inlay Wax Thermal Properties

- Thermal conductivity is very low

- They have a high coefficient of thermal expansion

- It has a linear expansion of 0.7% with an increase in temperature of 20 degrees C

3. Inlay Wax Distortion

- It is the most serious problem

- Occurs during the forming and removal of the pattern from the mouth or die

- Occurs due to

- Thermal changes

- Relaxation of stress due to

- Contraction on cooling

- Occluded gas bubble

- Change of shape of wax during molding

- From manipulation

- Time and temperature of storage

- A freshly made wax pattern tends to change its shape and size over a period of time

- Upon cooling it contracts and after it attains equilibrium, the pattern attains a state of dimensional stability

Inlay Wax Manipulation:

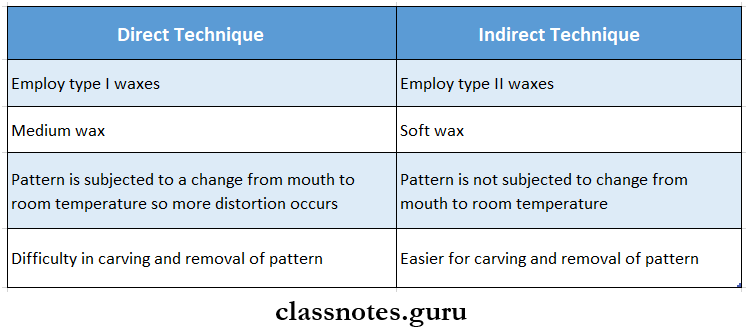

- Direct Technique

- Stick wax is softened over a flame

- It should be rotated until it becomes shiny

- It is repeated till the wax is warm throughout

- The wax is then kneaded together and shaped approximately to the form of a prepared cavity

- It is inserted into the cavity and held under finger pressure

- Wax should be cooled gradually at mouth temperature

- Withdraw the wax pattern carefully on the long axis of the preparation

- Indirect Technique

- Die is lubricated with lubricant containing a wetting agent

- An inlay pattern is prepared over it by either of the following methods

- Dipping method

- Die can be dipped repeatedly into the hot liquid wax

- Addition method

- The melted wax may be added in layers or painted on with a brush

- The prepared cavity is overfilled and the wax is then carved to the proper contour

Properties Of Dental Waxes

Question 2. Classify and give the composition of various types of wax used in dentistry.

Answer:

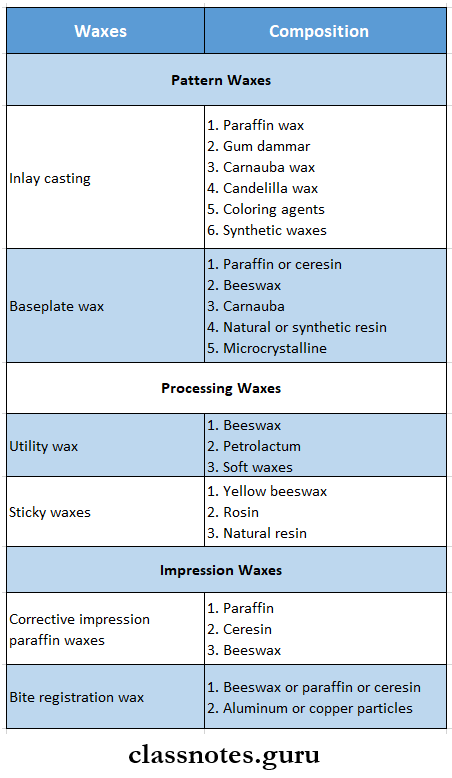

Classification of Waxes:

1. According to Origin

- Plant origin

- Carnauba wax

- Ouricury

- Candelilla

- Japan wax

- Mineral wax

- Paraffin wax

- Microcrystalline

- Barnsdahl

- Ceresin

- Insect

- Beeswax

- Animal

- Spermaceti

2. According to Use

- Pattern waxes

- Inlay casting

- RPD casting

- Baseplate

- Processing waxes

- Boxing wax

- Utility wax

- Sticky wax

- Impression waxes

- Corrective

- Bite registration

3. ADA classification- based on flow

- Type 1 – inlay casting wax

- Class 1-soft

- Class 2-hard

- Type 2-baseplate wax

- Class 1-soft

- Class 2- hard

- Class 3- extra hard

Composition of Waxes Used in Dentistry:

Question 3. What are the ideal requisites of inlay wax? Write in detail the composition, reasons for wax distortion, and methods to control the same.

Answer:

Ideal Requisites of Inlay Wax: When softened, the wax should be uniform

- Color should contrast with the die materials

- There should be no flakiness or surface roughening

- It should not chip, flake or tear during carving

- During burnout, it should vaporize completely without residue

- The wax pattern should be completely rigid and dimensionally stable at all the times

- Should be plastic slightly above mouth temperature and become rigid when cooled to mouth temperature

- Should have a good flow when heated and set rigidly when cooled

Wax distortion:

Wax distortion Causes:

- If the wax is not at uniform temperature when inserted in the cavity

- Some portions may contract more than other

- If the wax is not held under uniform pressure during cooling

- If fresh wax is melted and added in an area of deficiency, the added wax will introduce stresses during cooling

- During carving some molecules of wax will be disturbed and stresses will result

Wax distortion Prevention:

- After removal avoid touching the wax pattern with the fingers as much as possible to prevent any temperature changes

- Invest the pattern immediately after removal from the mouth or die

- Once investment hardens, there will be no more distortion of the pattern

- Minimal carving and change in temperature

- Store it in the refrigerator if necessary

Inlay Wax Vs Casting Wax

Question 4. Classify waxes used in Dentistry. Describe the composition, manipulation, and uses of Inlay wax.

Answer:

Inlay Wax Classification:

1. According To Origin

- Plant origin

- Carnauba wax

- Ouricry

- Candelilla

- Japan wax

- Animal origin

- Spermaceti

- Insect

- Beeswax

- Mineral origin

- Paraffin wax

- Microcrystalline

- Barnsdahl o Ceresin

2. According to Use

- Pattern waxes

- Inlay casting

- RPD casting

- Base plate

- Processing wax

- Boxing wax

- Utility wax

- Sticky wax

- Impression was a Corrective

- Bite registration

3. ADA Classification – based On Flow

- Type 1 – inlay casting wax

- Class 1 – soft

- Class 2 – hard

- Type 2 – baseplate wax

- Class 1 – soft

- Class 2 – hard

- Class 3 – extra hard

Inlay Wax

Inlay Wax Manipulation

- Direct Technique

- Stick wax is softened over a flame It should be rotated until it becomes shiny

- It is repeated till the wax is warm throughout

- The wax is then kneaded together and shaped approximately to the form of a prepared cavity o It is inserted into the cavity and held under finger pressure

- Wax should be cooled gradually at mouth temperature

- Withdraw the wax pattern carefully on the long axis of the preparation

- Indirect Technique

- Die is lubricated with lubricant containing a wetting agent

- An inlay pattern is prepared over it by either of the following methods

- Dipping method – die can be dipped repeatedly into the hot liquid wax

- Additional method – the melted wax may be added in layers or painted on with a brush

- The prepared cavity is overfilled and the wax is then carved to the proper contour

Inlay Wax Uses:

- Type 1 – rarely used

- Type 2 – used in direct technique

- Type 3 – used in an indirect technique for inlays, onlays, and full crown

Dental Waxes Short Essays

Question 1. Causes and prevention of wax distortion.

Answer:

Wax Distortion Causes:

- If the wax is not at uniform temperature when inserted in the cavity

- Some portions may contract more than other

- If the wax is not held under uniform pressure during cooling

- If fresh wax is melted and added in an area of deficiency, the added wax will introduce stresses during cooling

- During carving some molecules of wax will be disturbed and stresses will result

Wax Distortion Prevention:

- After removal avoid touching the wax pattern with the fingers as much as possible to prevent any temperature changes

- Invest the pattern immediately after removal from the mouth or die

- Once investment hardens, there will be no more distortion of the pattern

- Minimal carving and change in temperature

- Store it in the refrigerator if necessary

Dental Waxes For Prosthodontics

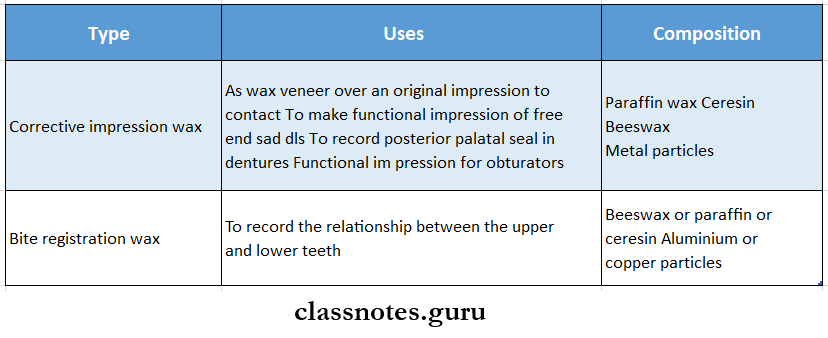

Question 2. Impression waxes

Answer:

Impression Waxes

- Impression waxes are used to record non-edentulous portions of the mouth

- Generally used in combination with other impression materials

Dental Waxes Short Question And Answers

Question 1. Name types of inlay wax and other waxes used in dentistry.

(or)

Types of wax

Answer:

Types of Inlay Waxes:

Other Waxes Used In Dentistry:

1. Pattern Waxes

- Inlay casting

- RPD casting

- Baseplate

2. Processing Waxes

- Boxing wax

- Utility wax

- Sticky wax

3. Impression Waxes

- Corrective

- Bite registration

Question 2. Baseplate Wax

Answer:

Baseplate Wax

- It is referred to as modeling wax

- They are classified under pattern waxes because they are used in the construction of dentures and appliances made of acrylic and like materials

Baseplate Wax Uses:

- To make occlusal rims

- To form a contour of the denture after teeth are set

- To make patterns for orthodontic appliances and other prostheses

Classification Of Dental Waxes

Question 3. Sticky Wax

Answer:

Sticky Wax

- It is quite tacky when melted

- Becomes firm and brittle when cooled

- It is used to join and temporarily stabilize the components of a bridge before soldering the pieces of the broken denture before the repair

Question 4. Bite registration wax.

Answer:

Bite Registration Wax

- It is the most versatile

- Easy to manipulate

- When softened uniformly it remains soft for adequate working time

- The flow at 37.5°C varies from 2.5% to 22%

- It is susceptible to distortion on removal from the mouth

Bite Registration Wax Uses:

To record the relationship between upper and lower teeth

Bite Registration Wax Composition:

- Beeswax or paraffin or ceresin

- Some may contain aluminum or copper particles

Bite Registration Wax Supplied As:

U-shaped rods or wafers

Bite Registration Wax Procedure:

- The wax is softened in warm water

- The soft wax is placed in the patient’s mouth and asked to bite

- After the wax hardens wax is removed and cooled

- Replaced again in mouth to check

- The cast is poured into indentations formed by teeth and then mounted over an articulator

Question 7. Causes of distortion of inlay wax pattern.

Answer:

Causes Of Distortion Of Inlay Wax Pattern

- If the wax is not at uniform temperature when inserted in the cavity

- Some portions may contract more than other

- If the wax is not held under uniform pressure during cooling

- If fresh wax is melted and added in an area of deficiency, the added wax will introduce stresses during cooling

- During carving, some molecules of wax will be disturbed and stresses will result