Cast Metal Restorations Important Notes

1. Pickling

- Pickling is the process of cleaning the gold casting with 50% warm HCl

- Used to remove surface oxides from casting

- Pickling is not a routine procedure

- Used only when indicated

2. Casting Defects

- Distortion

- Surface roughness and irregularities

- Discoloration

- Porosity

- Solidification defects

- Trapped gases

- Residual air

Read And Learn More: Operative Dentistry Question And Answers

3. Types Of Casting Machines

- Centrifugal Casting Machine

- Uses centrifugal force to accelerate the flow of molten metal into the mold space

- Air pressure Casting Machine

- Compressed gas is used to force the molten alloy into the mold

4. Types Of Cast Metal Alloys

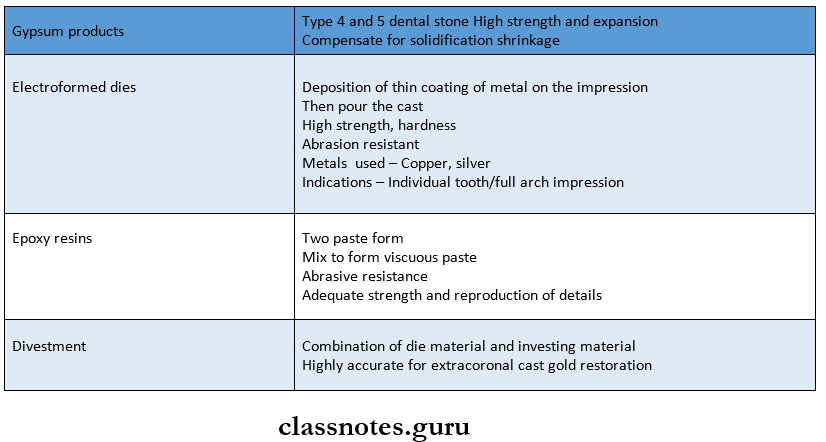

5. Types Of Die Materials Used

- Gypsum products

- Electroformed dies

- Epoxy resins

- Divestment

6. Properties Of Base Metal Alloys

- Low density

- Low percentage elongation

- High fusing temperature

- High hardness

- Tarnish and corrosion resistance

7. Retention Forms In Cast Restorations

- Grooves

- Bevel

- Internal box

- External box

- Pins, slots, skirt, collar

- Cusp capping

- Reciprocal retention

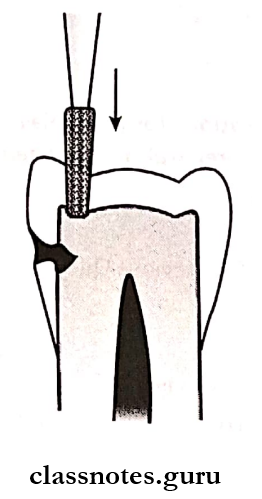

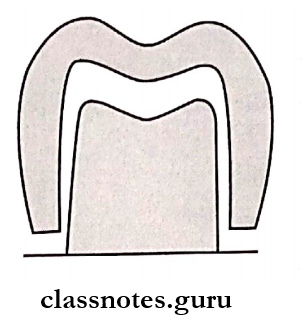

8. Onlay

- They are partly intracoronal and partly extra-coronal types of restoration

- Onlay has cuspal protection

- Onlay is mainly indicated when the width of the lesion exceeds one-third of the intercuspal distance

- Features of cavity preparation:

- Capping of functional cusps

- Cuspal reduction 1.5 mm

- The bevel used is a hollow ground long bevel in the intracoronal portion and a counter bevel in the extra coronal portion

- Table:

- Onlay is a transitional area between the intracoronal and extra-coronal portion

- Onlay should be flat

- Relieved from opposing cusps by 1.5 mm

- There should be 3 tables prepared for each cusp in different directions

- Onlay provides retention and resistance form

- Shoeing of nonfunctional cusps

- Provides retention and resistance form over the nonfunctional cusp

9. Composition Of Wax

10. Principles For Correct Spring

- Use of proper gauge of sprue

- Use of proper length of sprue

- Should be attached to the bulkiest portion of the wax pattern

- Attach it to the wax pattern with little heat to avoid distortion

11. Uses Of Casting Ring Liner

- Permits unrestricted expansion of the investment

- Acts as a cushion between rapidly cooling metal ring and the more slowly cooling investment during the casting and crystallization of gold

12. Objectives Of Burnout

- Complete removal of wax pattern

- Elimination of excess water from the investment

- Production of thermal expansion

Cast Metal Restorations Long Essays

Question 1. Classify casting defects describe mesioocclusal cavity preparation for gold inlay on a mandibular first molar.

(or)

Describe class 2 mesioocclusal cavity preparation for gold inlay on mandibular 1 molar tooth.

Answer:

Casting Defects:

- Distortion

- Surface roughness and irregularities

- Discoloration

- Porosity

- Solidification Defects

- Localized shrinkage

- Micro

- Trapped Gases

- Pinhole

- Gas inclusion

- Subsurface

- Residual Air

- Back pressure

- Solidification Defects

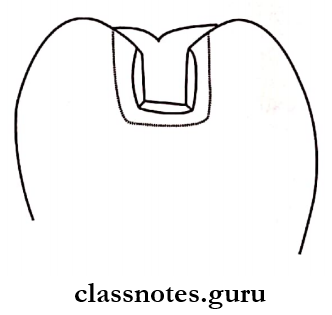

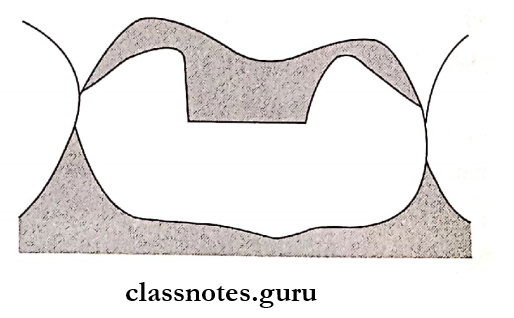

Class 2 Inlay Cavity Preparation

1. Initial Tooth Preparation

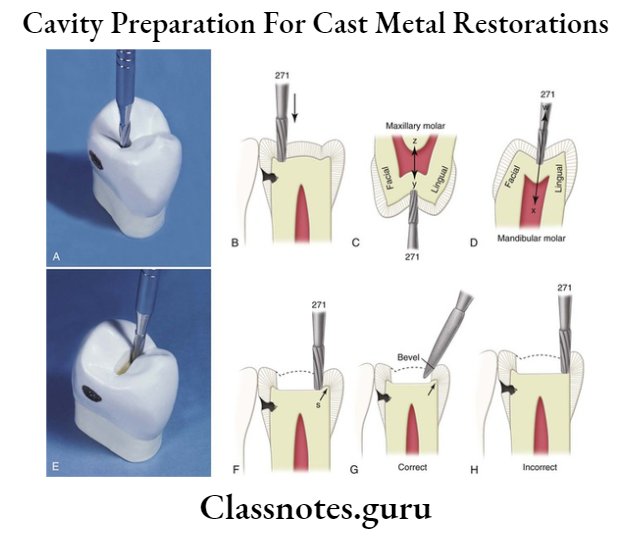

Occlusal Outline Form:

- Anesthetize and isolate the tooth

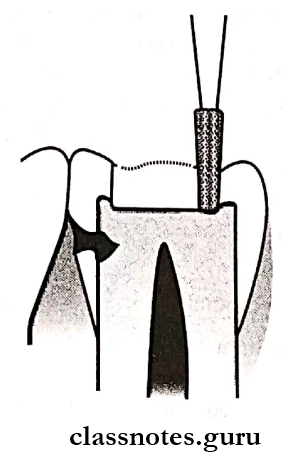

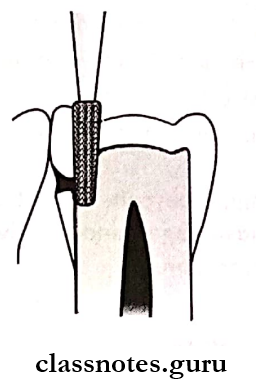

- Penetrate the tooth with no.271 bur from the mesial surface

- Extend upto central fissure to uninvolved marginal ridge

- Maintain a uniform pulpal depth of 1.5mm

- Preserve distal marginal ridge

- Extend up to the smooth areas of the buccal and lingual slopes of the cusps of a tooth.

Proximal Box Preparation:

- Mesial ditch cut is given using the same bur

- Width of cut 0.8mm, 0.5 mm in dentin, and 0.3 mm in enamel

- Extend it faciolingually

- Extend gingivally

- Provide 0.5mm of clearance

- Break the contact using cuts over facial and lingual walls using No.271 bur

Resistance And Retention Form:

- Flat pulpal floor

- Box-shaped preparation

- The extra thickness of gold

- Occlusal step

- Dovetail

2. Final Preparation:

1. Removal Of Remaining Caries, Old Restorative Material

- Removal of soft caries and infected dentin with a spoon excavator

2. Pulp Protection

- Use of pulp protective materials

3. Secondary Resistance And retention Forms

- Retention grooves were placed in the facial axial and in coaxial line angles using 169L carbide bur

- Bevels

- Gingival bevel 45° to the preparation

- Include one-half the width of the gingival wall

- Occlusal bevel At occlusal 1/3rd of adjacent occlusal wall

- Removes unsupported enamel

4. Inspecting, Cleaning, And Rinsing

- Clean the prepared tooth with air/water spray

- Dry it with a cotton pellet

- Inspect the angles and margins

Question 3. Define Inlay Describe the Indications, Contraindications, advantages, and disadvantages of cast gold restoration.

Answer:

Definition Of Inlay:

- An inlay is an indirect intracoronal restoration which is fabricated extra orally and cemented in the prepared tooth

Inlay Indications:

- Extensive proximal caries

- Patients with good oral hygiene and low caries index

- Postendodontic restoration

- Teeth with extensive restoration

- To maintain proper tooth contact and contour

- Presence of cast metal restoration

- Abutment teeth

- Teeth with heavy occlusal forces and attrition

Inlay Contraindications:

- Aesthetic consideration

- Patients with high caries index

- Young patients

- Periodontally weak teeth

- Extensive caries involving facial and lingual and multiple surfaces

- Low economic status

- Presence of dissimilar restoration

- Extensive occlusal wear facets

Inlay Advantages:

- Better reproduction of details

- Better wear resistant

- Biocompatible

- Strengthens remaining tooth structure

- Fewer chances of voids

- Easy to polish

- Less chair time

Inlay Disadvantages:

- Need of temporary restoration

- Expensive

- Technique sensitive

- Difficult to repair

- Weak tooth bonding

- Unesthetic

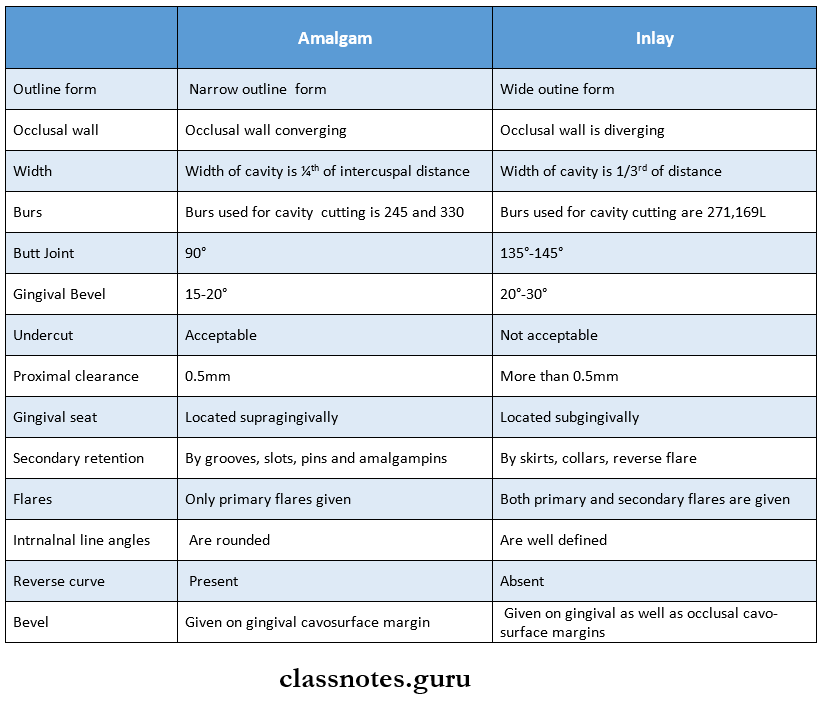

Question 4. Give the difference in cavity preparation between amalgam and gold inlay.

Answer:

Differences In Cavity Preparation Between Amalgam And Gold Inlay:

Question 5 Define retention form. How it is achieved in cast restoration.

Answer:

Retention Form:

- Retention Form is that form of cavity that resists the displacement of restoration from tipping and lifting forces

Retention In Cast Restorations:

1. Grooves:

Resist lateral displacement of restoration

- Internal Grooves

- Indicated in a shallow and small cavity

- Contraindicated in a deep cavity

- External Grooves

- Indicated in extra coronal preparation

- Prevents dislocation

- May be prepared in stepped form

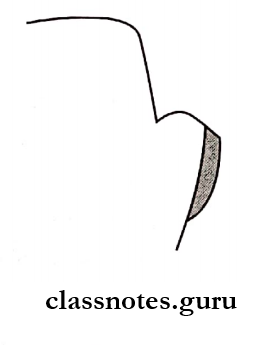

2. Reverse Bevel:

- Indication Class 1, 2, 3 restoration

- Presence of sufficient gingival floor

- Placed over the gingival floor with an incline gingivally and axially

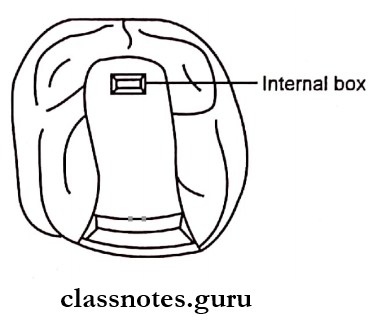

3. Internal Box:

- Indicated in the presence of sufficient dentin

- Contraindicated in class IV and V preparation

- Have vertical walls prepared in dentin

- Increases retention

- It should be 2 mm in dimension

4. External box:

- Box with an opening to the axial surface of the tooth

- The peripheral portion can be flared/beveled

5. Pins:

- Types of pins used Cemented, threaded, parallel, cast, and wrought

6. Slot:

- Indicated in the shallow cavity, restricted occlusal anatomy

- Have a depth of 23mm

7. Skirt:

- Indicated in missing wall

8. Collar:

- Depth 1.52mm, surface extension

- Indication Grossly carious teeth

- Short teeth

9. Cusp Capping:

- Provide sufficient height of cusp

10. Reciprocal Retention:

- Placement of retention made at every end of the preparation

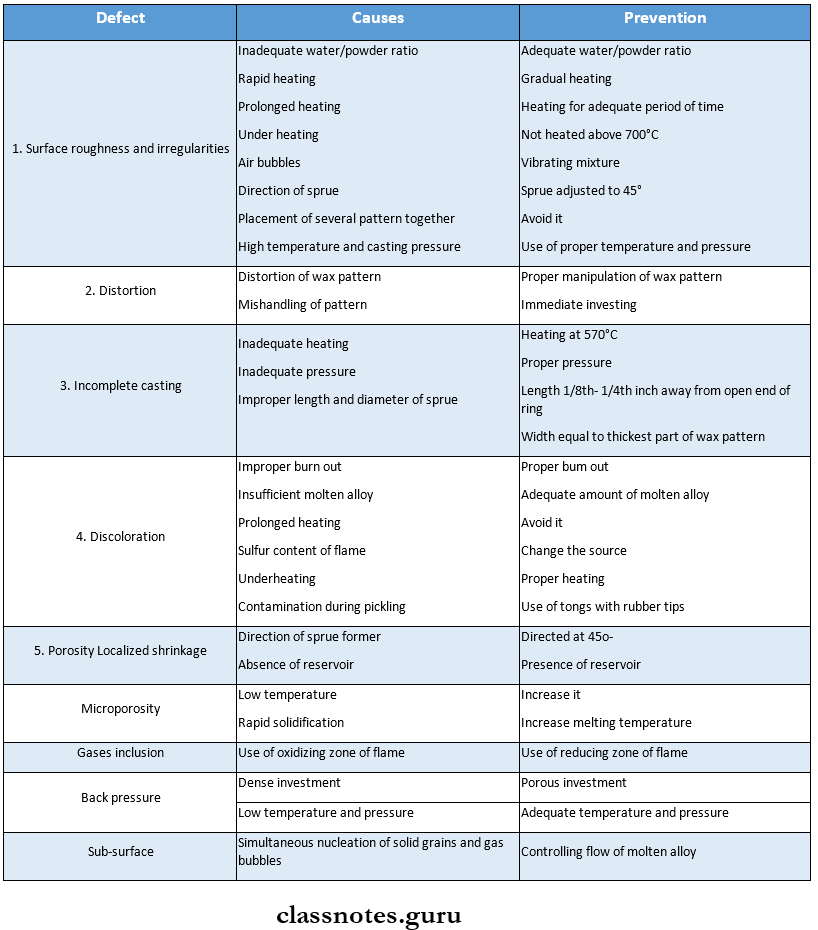

Question 6. Discuss the causes of casting defects and their prevention.

Answer:

The Causes Of Casting Defects And Their Prevention:

- Casting defects can be prevented by following various steps systematically

- Types of casting defects along with their causes and prevention are as follows

Cast Metal Restorations Short Essays

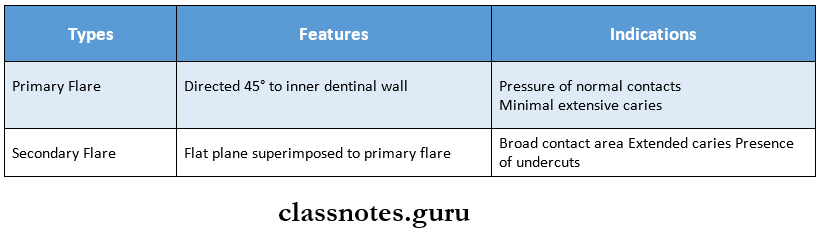

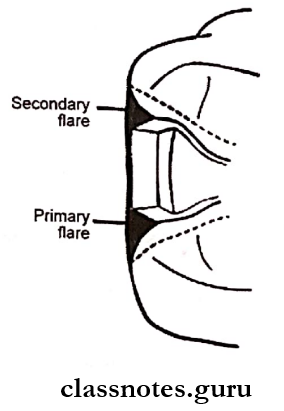

Question 1. Bevel and flares.

or

Circumferential Tie.

Answer:

Circumferential Tie:

- Circumferential Tie refers to the design of the cavosurface margin of an inlay tooth preparation

Significance:

- The cavosurface margin is the weakest part of the restoration

- To strengthen it, it is designed by incorporating bevels and flares

1. Bevels:

- Bevels is the inclination that one surface makes with another when not at right angles

Bevels Types:

- Partial Bevel

- Involving less than 2/3rd of enamel

- Use of type 1 casting alloys

- Short Bevel

- Involves full thickness of enamel

- Use of type 1 and 2 alloys

- Long Bevel

- Involves full enamel and half dentin

- Use in type 1, 2, and 2 alloys

- Full Bevel

- Involves complete enamel and dentin

- Hollow ground Bevel

- Concave in shape

- Counter Bevel

- In cases of cusp capping

1. Flares: They are concave/flat peripheral portions of the facial/lingual proximal walls

Question 2. Die materials.

Answer:

Die materials Properties:

- Compatible with impression materials

- Have smooth surface

- Have adequate strength

- Easy to fabricate

- Have contrasting color

- Reproduce accurate details

Die materials Materials:

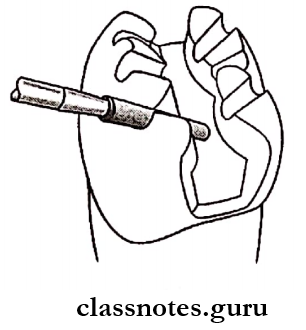

Question 3. Direct Wax Pattern.

Answer:

Direct Wax Pattern:

- Prepared in the oral cavity

- Done using matrix band or without it

Direct Wax Pattern Technique:

Isolate the tooth

↓

Apply band and retainer

↓

Soften inlay wax

↓

Compress over the prepared tooth

↓

Hold it with finger pressure til it sets

↓

Burnish it

↓

Remove band and retainer

↓

Check for centric occlusion

↓

Check for high points

↓

Smoothen it

↓

Attach sprue former and reservoir

↓

Remove the wax pattern

Direct Wax Pattern Advantages:

- Fewer discrepancies

- Less laboratory work

Direct Wax Pattern Disadvantages:

- Require more skill

- Requires more chair side time

Question 4. Indirect Wax Pattern.

Answer:

Indirect Wax Pattern:

- Prepared outside the oral cavity

- Use of type 11 inlay wax

Indirect Wax Pattern Steps:

Lubricate the die

↓

Adapt inlay wax over it

↓

Carve the wax

↓

Attach sprue former

↓

Remove the wax pattern

Indirect Wax Pattern Advantages:

- Less chair time

- Finishing and polishing

- This can be done on a die

Indirect Wax Pattern Disadvantages:

- More laboratory work

- Errors due to inadequate casting

Question 5. Sprue.

Answer:

Sprue:

- Provides a channel so that molten metal flows into mold space after the wax pattern has been eliminated.

Sprue Types:

- Wax

- Plastic

- Metal

Sprue Functions:

- Provides a channel for the flow of molten alloy

- Provides reservoir to compensate for shrinkage

- Provides a channel for wax elimination

Sprue Requirements:

- Diameter Greater than the thickest part of the wax pattern

- Attachment to the thickest part of the wax pattern

- Sprue length such that the end of the wax pattern is l/8th to l/4th inch away from the open end of the casting ring

- Direction 45 to the bulkiest portion of the wax

- ReservoirTo compensate shrinkage

Question 6. Casting machines.

Answer:

Casting machines Types:

1. Centrifugal Casting Machine:

- Cheapest

- Used for small casting

- Uses centrifugal force to accelerate the flow of mol¬ten metal into the mold space

Casting Machines Steps:

Heat the ring at 1200°F for 15 minutes

↓

Move the arm of casting machine 23 turns clockwise and

lock it

↓

Heat the gold alloy

↓

Place the ring in the casting machine

↓

Release the lock of the arm

↓

This forces molten gold into a mold

↓

Recover the ring from the casting machine and cool it

↓

Removes the casting and cleans it

2. Air pressure Casting Machine:

- Compressed air/gases like carbon dioxide or nitrogen are used to force the molten alloy into the mold.

Question 7. CADCAM for Inlay.

Answer:

CADCAM For Inlay:

- CADCAM indicates Computer Aided Design Computer Aided Machine

- In it, the whole casting design is fabricated

- This design is fed up with the computer

- The whole design is scanned

- It is then fabricated into the final prosthesis

- The computer is connected to a machine that processes the prosthesis

- Thus, the machining process of the prosthesis according to the design fabricated by the computer

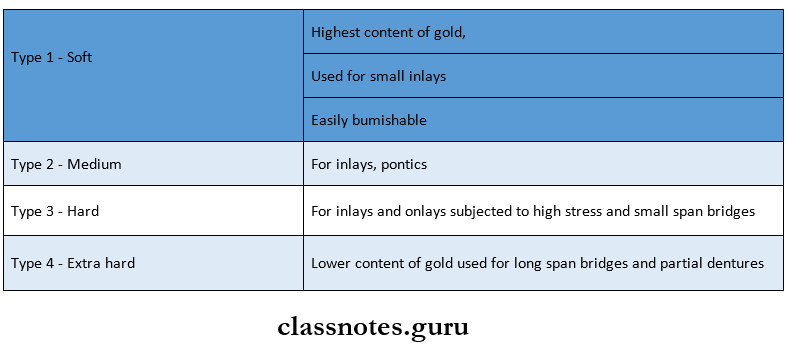

Question 8. Types of Cast Gold Alloys.

Answer:

Types of Cast Gold Alloys:

Type 1 Soft

- Used for fabrication of small inlays

- Low strength

- Easily burnished

- Gold content7583%

Type 2 Medium

- Used for fabrication of inlays and onlays subjected to moderate stresses

- Cannot be heat treated

- Gold content7075%

Type 3Hard

- Used for high-stresses

- High strength

- Can be heat-treated

- Gold content6570%

Type 4 Extra Hard:

- Used for crowns, bridges, and removable partial dentures

- Increased hardness

- Can be heat-treated

- Gold content 60%

Question 9. Indications and contraindications of Onlay

Answer:

Indications And Contraindications Of Onlay:

Only:

- Indications And Contraindications Of Onlay is a combination of intracoronal and extra-coronal cast restoration which covers one or more cusps

Indications And Contraindications Of Onlay Indications:

- Extensive weakened tooth due to caries or large restoration

- As post-endodontic restoration

- Presence of other cast restorations in adjacent or opposing teeth

- When the mesiodistal diameter of the tooth needs to be extended

- To correct the occlusal plane

- As an abutment for RPD

Indications And Contraindications Of Onlay Contraindications:

- Patients with high caries rate

- Young patients

- Short clinical crown height

Cast Metal Restorations Short Answers

Question 1. Reverse bevel.

Answer:

Reverse Bevel:

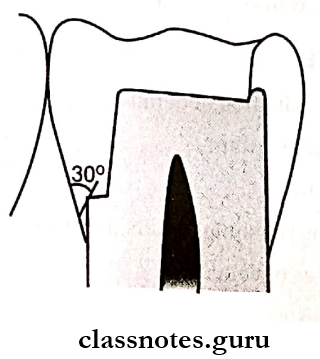

- A reverse bevel is a bevel of generous width that is prepared on the facial margin of a reduced cusp with a flame-shaped, fine grit diamond instrument

- Reverse Bevel width should extend beyond any occlusal contact with opposing teeth

- Reverse Bevel should be at an angle that results in a 30-degree marginal metal

- Reverse Bevel should be wide enough so that the cave surface margin is beyond any contact with the opposing dentition

Question 2. Sprue former.

Answer:

Sprue Former:

- A sprue former is made of wax, plastic, or metal

- Thickness is in proportion to the wax pattern

Sprue Former Functions:

- To form a mount for the wax pattern

- To create a channel for the elimination of wax during burnout

- Forms channel for entry of metal which compensates for allo£ shrinkage during solidification

Question 3. Porosities in casting.

Answer:

Porosities In Casting:

Porosities In Casting Types:

1. Caused By Solidification Shrinkage

- Localized shrinkage porosity

- Suck back porosity

- Microporosity

2. Caused By Gas

- Pinhole porosity

- Gas inclusion

- Subsurface porosity

3. Caused By Air Entrapment:

- Back pressure porosity

Porosities In Casting Prevention:

- Use of correct sprue thickness

- Correct placement of sprue

- Use of reservoir

- Use of adequate casting forces

- Use of porous investment and proper vents

- Place the pattern away from the end of the ring

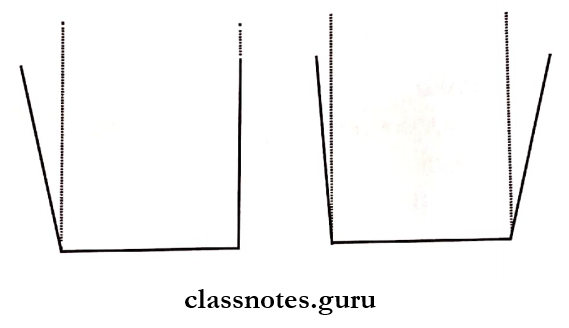

Question 4. Inlay Taper.

Answer:

Inlay Taper:

- Ideally, a tooth preparation should have slight diverg¬ing walls from gingival to occlusal surface

Inlay Taper Value:

- Optimal taper25° per wall

- For short longitudinal walls 2° taper

- For high longitudinal walls Increased but not more than 10°

- Preparation should never have one side with more taper than the other

- For shallow preparation Axis of the taper is parallel to the long axis of the tooth

- For class 5 Axis of the taper is perpendicular to the long axis of the tooth.

Question 5. Hot spot porosity.

Answer:

Hot Spot Porosity:

- Hot Spot Porosity is localized shrinkage porosity

- Occurs due to shrinkage of molten alloy when alloy solidifies from a molten state

- Cause Sprue former directed at 90°

- Prevention Direct the sprue former at 45°

Question 6. Back pressure porosity.

Answer:

Back Pressure Porosity:

- This is caused by inadequate venting of the mold

- If the bulk of the investment is too great the escape of air becomes difficult causing increased pressure in the mold

- The gold will solidify before the mold is filled resulting in a porous casting with rounded short margins

- Avoided by

- Using adequate casting forces

- Use of investment of adequate porosity

- Place the pattern not more than 68 mm from the end of the ring

Question 7. Subsurface porosity.

Answer:

Subsurface Porosity:

- Subsurface Porosity is porosity caused by gas

Subsurface Porosity Cause:

- Simultaneous nucleation of solid grains and gas bubbles

Subsurface Porosity Prevention:

- Controlling the flow of molten alloy

Question 8. Electroformed dies.

Answer:

Electroformed Dies:

Subsurface Porosity Advantages:

- Dimensional accurate

- Hard, abrasion-resistant

- Imparts a smooth surface

- Cheap

- Better marginal definition

- Does not absorb oil or water

- Prevent cuspal wear

Subsurface Porosity Disadvantages:

- Difficult to trim

- Silver bath health hazard

- Noncompatible with impression material

- Color contrast is not good

- or adaptation to wax

- The pattern tends to lift from margins

Question 9. Onlay.

Answer:

Onlay:

- Onlay It is a combination of intracoronal and extra-coronal cast restoration which covers one or more cusp

Tooth Preparation:

- Occlusal Outline Form:

- Isolate the tooth

- Start preparation with 271 bur

- Maintain a pulpal depth of 2 mm

- Reduce the cusps

- Occlusal divergence 3°-5°

Proximal Box Preparation:

- Extend the preparation both mesially and distally

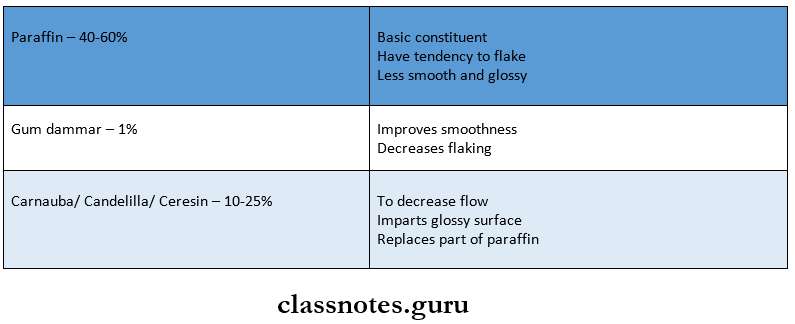

Question 10. Inlay Wax.

Answer:

Inlay Wax:

Inlay Wax Properties:

- Plasticity

- Solid below approximately 40°C

Inlay Wax Types:

- Type 1

- Type 2

Inlay Wax Composition:

- Paraffin wax- 40 60%

- Ceresin -10%

- Gum dammar- 1%

- Carnauba- 25%

- Coloring agents

Question 11. Localized shrinkage porosity

Answer:

Localized Shrinkage Porosity:

- Occurs when cooling is incorrect

- The sprue freezes before the rest of the casting

- It results in large irregular voids near the sprue casting interface

Localized Shrinkage Porosity Prevention:

- Sprue former should be directed at 45 degrees

- Placement of reservoir

Cast Metal Restorations Viva Voce

- Sprue former diameter is between 8018 gauge

- Types of sprue former wax, metal, and resin

- Occlusal bevel in inlay3045°

- Gingival bevel in inlay 30°

- The sprue is placed at a 45° angle to the wax pattern

- Wax interocclusal records help check occlusal clearance

- Binder present in investment provides strength

- Casting ring liner helps in permitting the expansion of mold

- Sprue should be positioned in the thickest portion of the wax pattern

- There should be a minimum gap of 1/8 1/4th inch between the ends of the casting ring and wax pattern

- Back pressure porosity is caused by the entrapped air in the mold that does not escape through the pores of the investment

- Type 1 or type B wax is used for the direct technique of wax pattern construction

- Type C is used for indirect technique