Wrought Alloys Important Notes

1. Stainless Steel.

- Austenitic stainless steel

- Use – To make orthodontic archwires

Stainless Steel Properties:

- Adequate strength

- Adequate spring back

- Resilience

- Formability

- Biocompatible

- Economical

2. Alloys And Their Constituents

- Elgiloy-cobalt-chromium-nickel

- Beta titanium – titanium – molybdenum – aluminum

- Nitinol-nickel-titanium

- Titanium alloys – titanium – aluminum – vanadium

Wrought Alloys Short Essays

Question 1. Ni-Ti orthodontic wire.

Answer:

Ni-Ti orthodontic wire

- Synonym – Nitinol (Nickel Titanium Naval Ordinance Laboratory)

- Inventor – William R. Buchler

- Introduced by – Andersen in 1971

Nickel Titanium Alloy Properties:

- Super elasticity

- Shape memory

- High spring back

- High working range

- Low stiffness

Read And Learn More: Dental Materials Question and Answers

Ni-Ti orthodontic wire Advantages or Nickel Titanium Alloy Properties:

Produce low and more constant force on teeth

Ni-Ti orthodontic wire Disadvantages or Nickel Titanium Alloy Properties:

- Cannot be bent

- Cannot be soldered or welded

Wrought Alloys In Dentistry

Question 2. Types of Stainless Steel.

Answer:

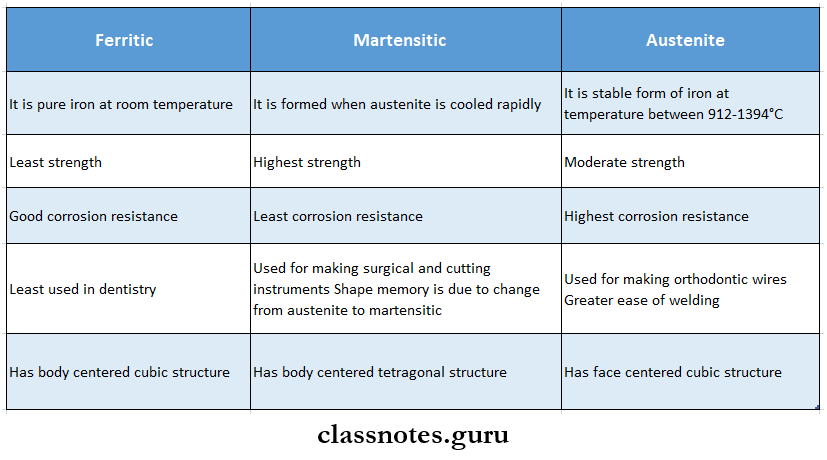

Types of Stainless Steel

- Types of stainless steel are

- Ferritic stainless steel

- Austenitic stainless steel

- Martensitic stainless steel

Sensitization Of Stainless Steel

Wrought Alloys Short Question And Answers

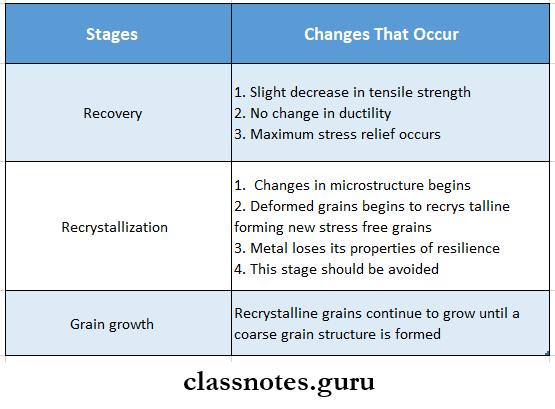

Question 1. Stages of annealing heat treatment.

Answer:

Stages Of Annealing Heat Treatment

Dental Wrought Alloys

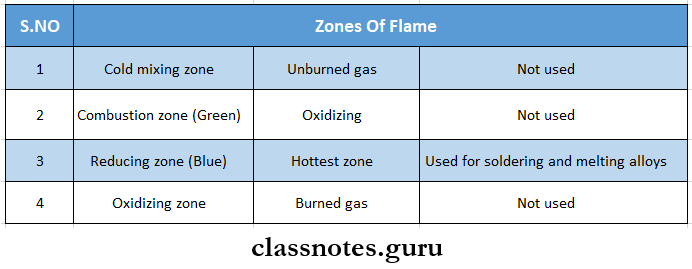

Question 2. Zones of flame.

Answer:

Zones Of Flame

Examples Of Wrought Alloys

Question 3. Sensitization of 18-8 stainless steel.

Answer:

Sensitization Of 18-8 Stainless Steel

- At 400-900°C, stainless steel resists corrosion and tarnish

- At lower temperatures, carbon reacts with the surface granules and forms chromium iron carbide causing tarnish and corrosion

- This can be prevented by decreasing carbon content or by cold working of stainless steel.