Dental Amalgam Important Notes

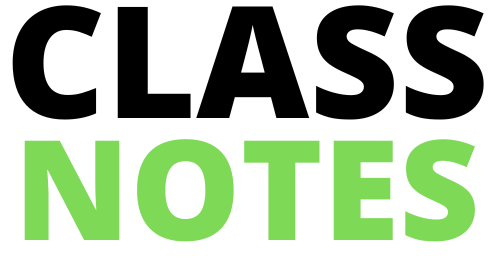

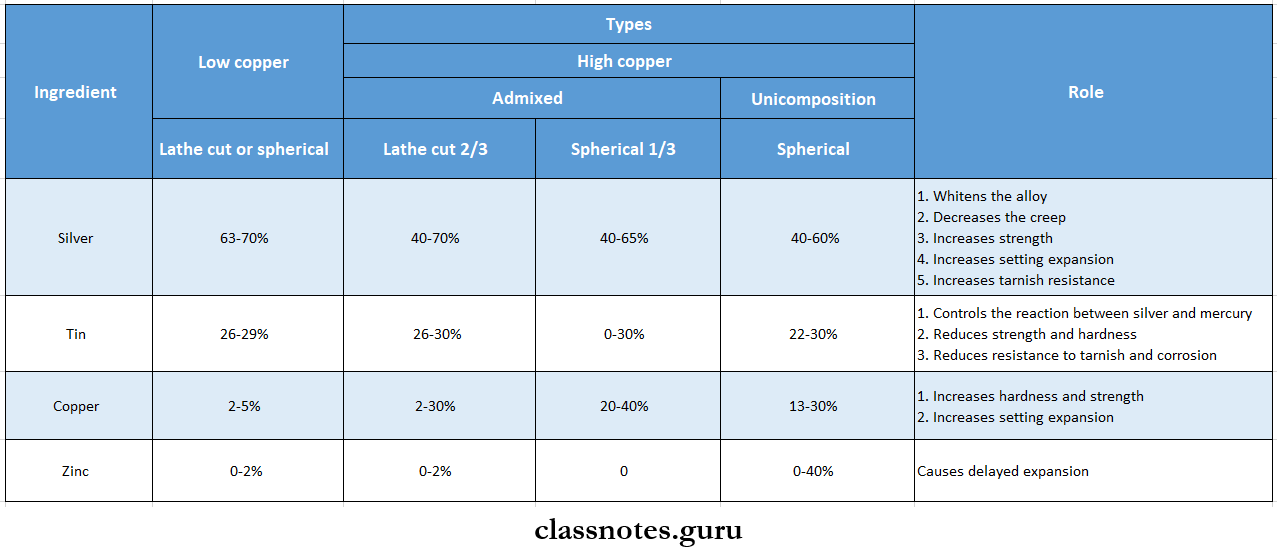

1. Composition of amalgam

Mercury In Dental Amalgam

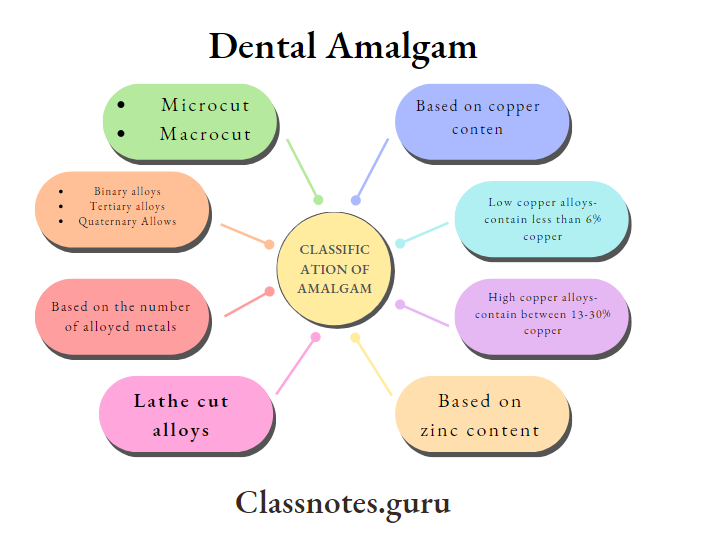

2. Classification of amalgam

- Based on copper content

- Low copper alloys contain less than 6% copper

- High copper alloys contain between 13-and 30% copper

- Based on zinc content

- Zinc-containing alloys

- Zinc-free alloys

- Based on the shape of the alloy particle

- Lathe-cut alloys

- Spherical alloys

- Based on the number of alloyed metals

- Binary alloys

- Tertiary alloys

- Quaternary alloys

- Based on the size of the alloy

- Microcut

- Macrocut

Dental Amalgam Composition Questions and Answers

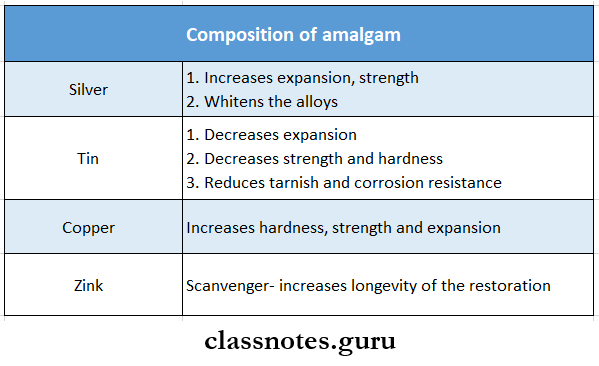

3. Phases of amalgam

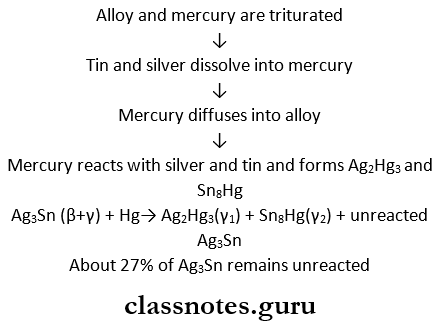

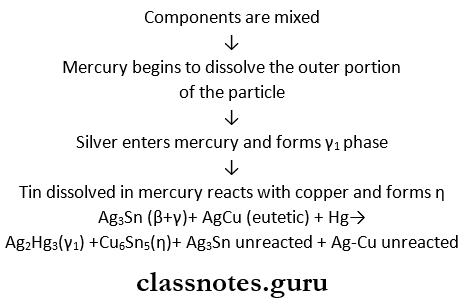

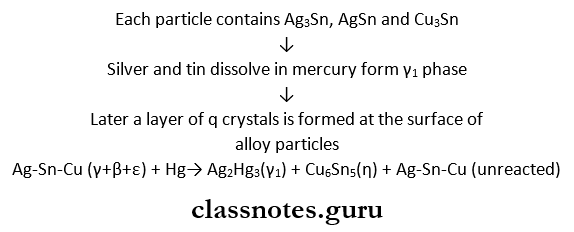

4. Setting reaction

- For low copper alloys

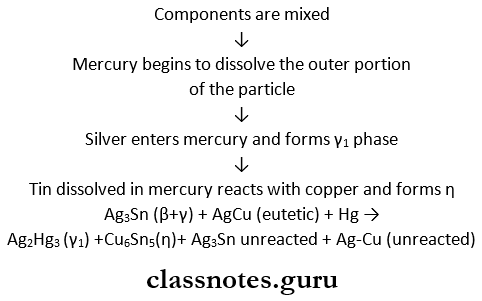

Ag3Sn + Hg → Ag2Hg3 + Sn8Hg + Ag3Sn (unreacted) - For high copper admixed alloys

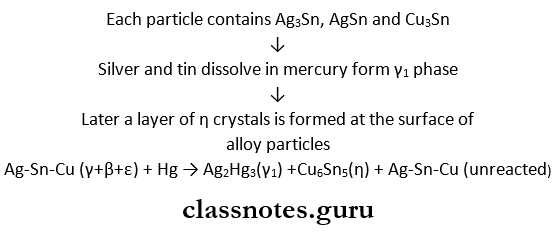

γ + Ag-Cu + Hg → γ1 + Cu6Sn5 + (γ + Ag-Cu) unreacted - For high copper single composition alloys Ag-Sn-Cu + Hg → γ1 + η + unreacted alloy particles (γ)

Dental Amalgam Composition Questions and Answers

Read And Learn More: Dental Materials Question and Answers

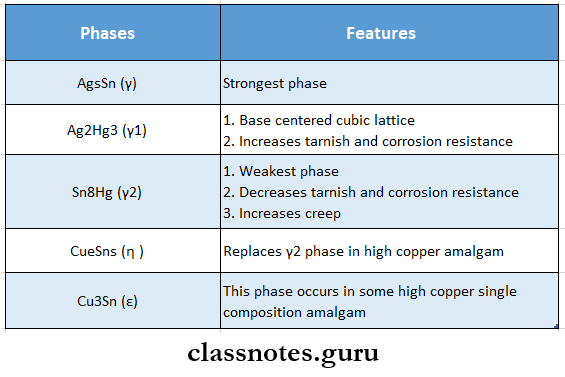

5. Lathe cut and spherical alloys

6. Eames’ technique

- It states the minimum mercury alloy ratio

- It should be 1:1

- The mercury content of the finished restoration should be approximately 50 wt%. For spherical alloys, it should be approximately 42 wt%

7. High copper alloys are superior to low copper alloys because:

- Higher resistance to tarnish, corrosion

- Lower creep

- High strength

- Elimination of SnHg phase

Alternatives to dental amalgam

8. Delayed expansion

- Occurs when zinc-containing alloys are contaminated with moisture during trituration or condensation

- Expansion reaches upto 400 pm/cm

- It occurs 3-4 days after insertion of amalgam

- It is due to the formation and accumulation of hydrogen gas in the restoration leading to pain, sensitivity, and proper sion of the restoration

Composition Of Dental Amalgam

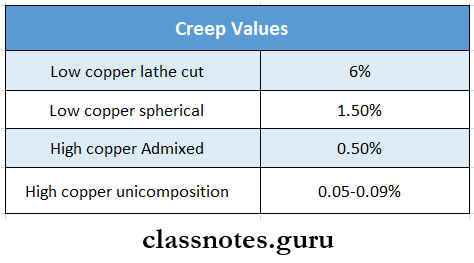

9. Creep

- It is defined as the time-dependent plastic deformation

- The higher the creep, the greater the marginal deterioration

- Values:

- Low copper – 0.8-8%

- High copper – 0.4-0.1%

Components Of Dental Amalgam

10. Tarnish and corrosion products

- Tarnish product – Ag2S

- Corrosion product

- Low copper – SnO, Sn-O-Cl

- High copper – SnO, Sn-O-Cl, CuO

Alternatives to dental amalgam

Dental Amalgam Long Essays

Question 1. Discuss the type, properties, and uses of dental amalgam alloys. Add a note on high copper alloys.

Answer:

Dental Amalgam:

Dental amalgam is an alloy of mercury, silver, copper, and tin which may also contain palladium, zinc, and other elements to improve handling characteristics and clinical performance.

Dental Amalgam alloys Types:

- Based on copper content

- Low copper alloys- contain less than 6% copper

- High copper alloys- contain between 13-30% copper

- Based on zinc content

- Zinc containing alloys

- Zinc free alloys

- Based on the shape of the alloy particle

- Lathe cut alloys

- Spherical alloys

- Spherical alloys

- Based on the number of alloyed metals

- Binary alloys

- Tertiary alloys

- Quaternary alloys

- Based on size of the alloy

- Microcut

- Macrocut

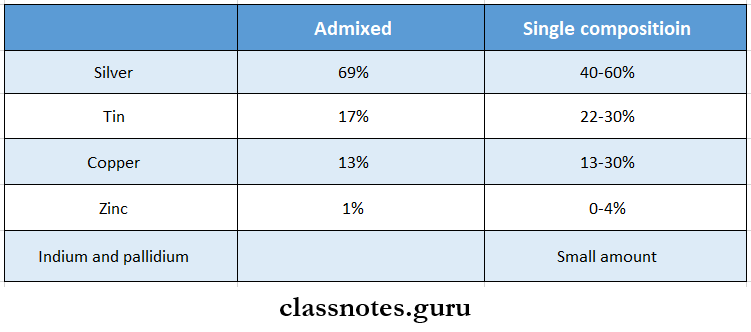

Dental amalgam composition

Dental Amalgam alloys Properties:

- Dimensional stability

- Amalgam may expand or contract depending on its manipulation

- Severe contraction can lead to microleakage, plaque accumulation, and secondary caries

- Excessive expansion can produce pressure on the pulp and postoperative sensitivity

- It can also lead to the protrusion of restorations

- Effect of moisture contamination

- If a zinc-containing low copper or high copper amalgam is contaminated by moisture during trituration or condensation, a large expansion results

- It usually starts after 3-5 days and may continue for months

- This is called delayed expansion

- Strength

- It lacks of strength to resist masticatory forces and thus fractures

- Creep

- It is a slow progressive permanent deformation of set amalgam that occurs under constant stress

- Higher the creep magnitude the greater the degree of marginal deterioration

- Tarnish and corrosion

- Amalgam restorations often tarnish and corrode the oral environment

- Retention

- Amalgam does not adhere to tooth structure

- Retention is by mechanical locking

- Microleakage

- Amalgam is a self-sealing restoration

- They are capable of sealing against, microleakage

Dental Amalgam Uses

Dental Amalgam alloys Use:

- As permanent restorative material for

- Class 1 and class 2 cavities

- Class 5 cavities

- In combination with retentive pins to restore a crown

- For making dies

- In retrograde root canal filling materials

- As a core material

Dental amalgam composition

High Copper Alloys:

- Contains 13-30%, weight copper

- They are preferred because of

- Improved properties

- Resistance to corrosion

- Better marginal integrity

- Improved performance in clinical trials

Copper Alloys Types:

- Admixed alloys 0 Regular type

- Unicomposition alloy

- Single composition alloy

Copper Alloys Composition:

Dental amalgam properties

Copper Alloys Setting reaction:

1. Admixed alloy

2. Single composition

Copper Alloys Advantages:

- Set fasts

- Low residual mercury

- Low creep

- Faster finishing

- High strength

- Low condensation pressure

Copper Alloys Disadvantages:

- Less working time

- Condensation pressure is not sufficient

Dental Amalgam Questions And Answers

Question 2. State various merits and demerits of dental amalgams

Answer:

Dental Amalgam:

Dental amalgam is an alloy of mercury, silver, copper, and tin which may also contain palladium, zinc, and other elements to improve handling characteristics and clinical performance.

Dental Amalgam Merits:

- Easy to insert

- Not technique sensitive

- Maintain anatomic form well

- Have adequate resistance to fracture

- Prevent marginal leakage after some time

- Have a reasonably long shelf life

Dental amalgam properties

Dental Amalgam Demerits:

- The color does not match the tooth color

- More brittle

- Less tough than desirable

- Subject to corrosion and galvanic action

- Show marginal breakdown

- Do not bond to tooth structure

Dental Materials Question And Answers

Question 3. Give the composition of dental amalgam alloys and write in detail about the manipulation and properties of high copper dental amalgam

Answer:

Amalgam alloys Composition:

- Mercury

- It is added to the alloy

- Platinum

- Hardens the alloy

- Increases resistance to corrosion

- Palladium

- Hardens and whitens the alloy

- Indium

- Reduces mercury vapor and improves wetting

Amalgam alloys Manipulation:

1. Selection of materials

- Alloy selection

- For therapeutic purposes- high resistance amalgam is selected

- For strength- high copper alloys are selected

- If moisture control is difficult- non-zinc-containing alloys are selected

- Mercury: alloy ratio

- To achieve smooth and plastic amalgam an amount of mercury in excess is desirable

- But because of the harmful effects of excess mercury, it is necessary to reduce the amount of mercury

- One of the methods for it is to reduce the original mercury/alloy ratio

- This is called the Eames technique e Sufficient mercury must be present in the mix and it should be as low enough so that mercury content is acceptable during condensation

- Ratio is 1:1

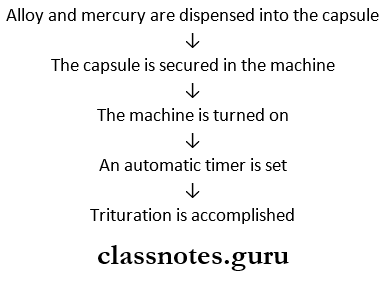

2. Amalgam alloys Trituration

- Objective

- To wet all the surfaces of the alloy particles with mercury

- The film should be rubbed off to obtain a clean surface of alloy for mercury

- Manual mixing

- A glass mortar with a roughened inner surface and a pestle with a round end are used for mixing

- It depends on

- Number of rotations

- Speed of rotations

- Pressure placed on pestle

- Amalgam alloys Mechanical mixing

Dental Amalgam Components

3. Amalgam alloys Mulling

- It is a continuation of trituration

- It causes the mix to cohere so that it can be readily removed from the capsule

- Achieved by vigorously rubbing between first finger and thumb for 2-5 sec

4. Amalgam alloys Condensation

- Amalgam is placed in a prepared cavity and condensed using suitable condensers

- Aims

- To compact alloy into a prepared cavity

- To remove any excess mercury in each increment

- Reduces voids

Dental Materials Question And Answers

5. Amalgam alloys Carving and finishing

- Carved to reproduce proper tooth anatomy

- Smoothen through burnishing with a ball burnisher

- Final smoothening can be achieved by rubbing with a moist cotton pellet

- Polishing minimizes corrosion and prevents adherence to plaque

- It is delayed for 24 hours

- Wet polishing is desirable

Dental Amalgam Components

Amalgam alloys Properties:

- Dimensional stability

- Amalgam may expand or contract depending on its manipulation

- Severe contraction can lead to microleakage, plaque accumulation, and secondary caries

- Excessive expansion can produce pressure on the pulp and postoperative sensitivity

- It can also lead to the protrusion of restorations

- Effect of moisture contamination

- If a zinc-containing low copper or high copper amalgam is contaminated by moisture during trituration or condensation, a large expansion results

- It usually starts after 3-5 days and may continue for months

- This is called delayed expansion

- Amalgam alloys Strength

- It lacks of strength to resist masticatory forces and thus fractures

- Creep

- It is a slow progressive permanent deformation of set amalgam that occurs under constant stress

- Higher the creep magnitude the greater the degree of marginal deterioration

- Tarnish and corrosion

- Amalgam restorations often tarnish and corrode the oral environment

- Retention

- Amalgam does not adhere to tooth structure » Retention is by mechanical locking

- Microleakage

- Amalgam is a self-sealing restoration

- They are capable of sealing against, microleakage

Advantages And Disadvantages Of Dental Amalgam

Question 4. Write in brief about the setting reaction of both low and high copper amalgam alloy. What are the phases formed during the reaction with a note on factors affecting its strength?

Answer:

Setting Reactions:

1. Low Copper Amalgam Alloys:

Uses Of Dental Amalgam

2. High Copper Amalgam:

Admixed alloy

3. Single composition:

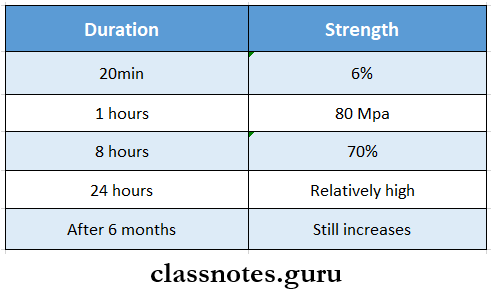

Amalgam Factors Affecting Strength:

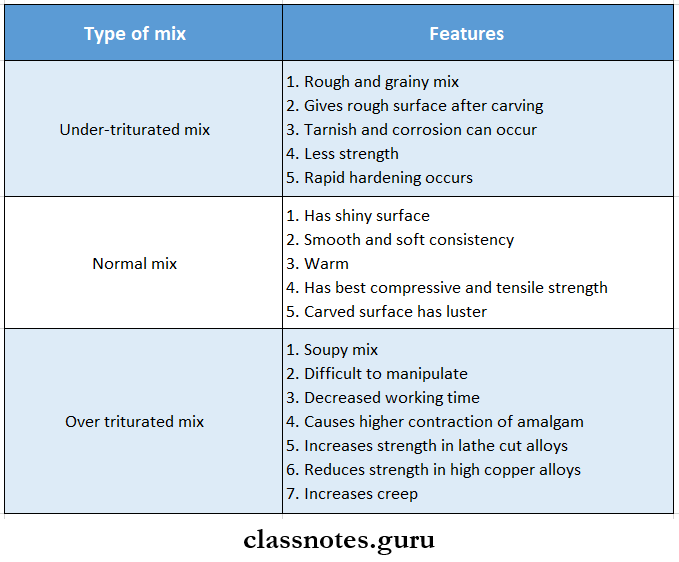

- Effect of trituration

Under-triturated and over-triturated both decrease strength in both low and high-copper alloys

- Effect of mercury

- Sufficient mercury should be mixed with an alloy

- Any excess mercury left in the restoration decreases the strength

- For both low and high copper amalgam, if mercury content increases more than 54%, strength decreases

- Effect of condensation

- For lathe-cut alloys- greater condensation pressure, higher compressive strength

- For spherical alloys- lighter condensation pressure produces adequate strength

- Effect of porosity

- If porosities are greater, strength is lower

- Effect of amalgam hardening rate

- Amalgam does not gain strength rapidly

Types Of Dental Amalgam

Question 5. Write the composition, properties, advantages, and disadvantages of amalgam alloys. Add a note on the classification of amalgam alloys.

Answer:

Dental amalgam:

Dental amalgam is an alloy of mercury, silver, copper, and tin which may also contain palladium, zinc, and other elements to improve handling characteristics and clinical performance

Amalgam alloys Properties:

- Dimensional stability

- Amalgam may expand or contract depending on its manipulation

- Severe contraction can lead to microleakage, plaque accumulation, and secondary caries

- Excessive expansion can produce pressure on pulp and postoperative sensitivity

- It can also lead to protrusion of restoration

- Effect of moisture contamination

- If a zinc-containing low copper or high copper amalgam is contaminated by moisture during trituration or condensation, a large expansion results

- It usually starts after 3-5 days and may continue for months

- This is called delayed expansion

- Strength

Dental Amalgam Composition

- It lacks the strength to resist masticatory forces and thus fractures

- Creep

- It is a slow progressive permanent deformation of set amalgam that occurs under constant stress

- Higher the creep magnitude the greater the degree of marginal deterioration

- Tarnish and corrosion

- Amalgam restorations often tarnish and corrode the oral environment

- Retention

- Amalgam does not adhere to tooth structure

- Retention is by mechanical locking

- Microleakage

- Amalgam is a self-sealing restoration

- They are capable of sealing against microleakage

Amalgam alloys Advantages:

- Easy to insert

- Not technique sensitive

- Maintain anatomic form well

- Have adequate resistance to fracture

- Prevent marginal leakage after some time

- Have a reasonably long shelf life

Amalgam alloys: Disadvantages:

- Color does not match with tooth color

- More brittle

- Less tough than desirable

- Object to corrosion and galvanic action

- Show marginal breakdown

- Do not bond to tooth structure

Uses Of Dental Amalgam

Amalgam alloys Classification:

1. Based on copper content

- Low copper alloys contain less than 6% copper

- High copper alloys contain between 13-30% copper

2. Based on zinc content

- Zinc containing alloys

- Zinc free alloys

3. Based on the shape of alloy particles

- Lathe cut alloys

- Spherical alloys

4. Based on the number of alloy metals

- Binary alloys

- Tertiary alloys

- Quaternary alloys

5. Based on size of alloys

- Microcut

- Macrocut

Components Of Dental Amalgam

Setting Reaction Of Dental Amalgam

Dental Amalgam Short Essays

Question 1. Trituration

Answer:

Trituration Objective:

- To wet all the surfaces of the alloy particles with mercury

- The film should be rubbed off to obtain a clean surface of alloy for mercury

Trituration Types:

- Trituration Manual mixing

- A glass mortar with a roughened inner surface and a pestle with a round end are used for mixing

- It depends on

- Number of rotations

- Speed of rotations

- Pressure placed on pestle

Trituration Advantages of Mechanical Mixing:

- Shorter mixing time

- More standardized procedure

- Requires less mercury

Dental Amalgam Setting Reaction

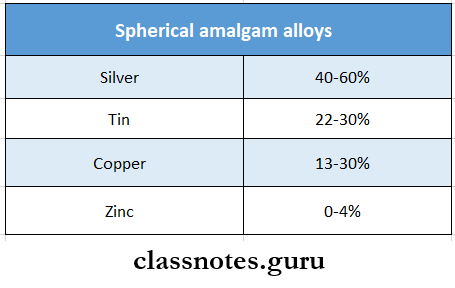

Question 2. Spherical amalgam alloys

Answer:

Spherical amalgam alloys

- Spherical amalgam alloy is prepared by the atomization process

- The liquid alloy is sprayed under high pressure of inert gas through a fine crack into a large chamber

Spherical amalgam alloys Features:

- Particles are small

- Manufactured by atomization process

- More plastic

- Need wedged matrix to establish proximal contour

- Require less mercury

- Particle size is- 5-40 pm

Spherical amalgam alloys Reactions:

- When triturated with mercury, silver, and tin dissolve in mercury

- γ1 crystals grow forming a matrix that binds together the partially dissolved alloy particles

Spherical amalgam alloys Composition:

Dental Amalgam Toxicity

Question 3. Amalgam capsule

Answer:

Amalgam capsule

- A capsule serves as a mortar

- A cylindrical metal or plastic piston of a smaller diameter than the capsule is inserted into the capsule and this serves as a pestle

- Alloy powder and mercury are separated by a membrane in it

- Before use the membrane is ruptured by compressing capsule and then placed in an amalgamator

Amalgam capsule Advantages:

- Consistent proportioning

- Low mercury/alloy ratio

- Physical handling is not required

Amalgam capsule Disadvantages:

- Mercury and alloy may leak

- Expensive

- Mercury hazards

Dental Amalgam Setting Reaction

Question 4. Delayed expansion of amalgam

Answer:

Delayed expansion of amalgam

- If a zinc-containing low copper or high copper amalgam is contaminated by moisture during trituration or condensation a large expansion results

- It usually starts after 3-5 days and may continue for months

- This is called delayed expansion

- H2O+ Zn → ZnO + H2 (gas) .

- This hydrogen gas does not combine with the amalgam but collects within the restoration, creating extreme internal pressure and expansion of the mass

- This causes

- Protrusion of the restoration

- Increased creep

- Increased microleakage

- Pitted surfaces and corrosion

- Dental pain

- Recurrence of caries

- Fracture of restoration

Dental Amalgam Uses

Question 5. Eames technique

Answer:

Eames technique

- To achieve smooth and plastic amalgam an amount of mercury in excess is desirable

- But because of the harmful effects of excess mercury, it is necessary to reduce the amount of mercury

- One of the methods for it is to reduce the original mercury or alloy ratio

- This is called the Eames technique

- Sufficient mercury must be present in the mix and it should be as low enough so that mercury content is acceptable during condensation

- Ratio is 1:1

Dental Amalgam Short Question And Answers

Question 1. High copper alloy

Answer:

High copper alloy

- Contains 13-30%, weight copper

- They are preferred because of

- Improved properties

- Resistance to corrosion

- Better marginal integrity

- Improved performance in clinical trials

High copper alloy Types:

- Admixed alloys

- Regular type

- Unicomposition alloy

- Single composition alloy

High copper alloy Advantages:

- Set fasts

- Low residual mercury

- Low creep

- Faster finishing

- High strength

- Low condensation pressure

High copper alloy Disadvantages:

- Less working time

- Condensation pressure is not sufficient

Dental Amalgam Setting Reaction

Question 2. Creep in amalgam

Answer:

Creep in amalgam

- It is a slow progressive permanent deformation of set amalgam that occurs under constant stress

- Higher the creep magnitude the greater the degree of marginal deterioration

- According to ADA’s specification, no 1 creep should be below 3%

Creep in amalgam Creep Values:

Creep in amalgam Factors Affecting Creep:

- Microstructure

- Manipulation

Question 3. Amalgam bond

Answer:

Amalgam bond

- Recently bonding agents like M-R-X type coupling agents have achieved success

- One system uses 4-methacryloxyethyl trimellitate anhydride

- Amalgam bonding agents have a place as an adjuvant to conventional retentive means if properly employed

Amalgam bond Mechanism Of Bonding:

- Bonding is mechanical

- Produced by condensing plastic amalgam mass into a plastic resin layer

- This produces macroretentive areas within the resin

Mercury In Dental Amalgam

Question 4. Gamma 2 phase in silver amalgam

Answer:

Gamma 2 phase in silver amalgam

The formula of γ2 is Sn8Hg

Gamma 2 phase in silver amalgam Importance:

- Weakest phase

- Decreases tarnish and corrosion resistance

- Increases creep

Dental Materials Question And Answers

Question 5. Mercury hygiene

Answer:

Mercury hygiene

- Follow aseptic technique

- Should have proper knowledge about mercury disposal and storage

- Use of proper ventilation

- Check mercury levels periodically

- Avoid carpet or floor covering

- Storage of mercury in a closed container in an isolated area

- Use of pre-capsulated alloy

- Use of amalgamators

- Polishing along with coolant

- Avoid direct contact with skin

- Use of evacuators

- Disposal in a closed plastic container

- Clean spilled mercury

- Remove protective clothing before leaving the operating area

Dental Amalgam Setting Reaction

Question 6. Advantages of high copper amalgam

Answer:

Advantages of high copper amalgam

- Set fasts

- Low residual mercury

- Low creep

- Faster finishing

- High strength

- Low condensation pressure